Rapid Prototyping and On-Demand Production for

Automation

Industry

Obtain high-quality manufacturing services for your custom automated production parts

Quality

Machining

Tolerances

Consistency

Services

One Stop for Your Automation Project Needs

Automation products enhances productivity, lowers costs, and strengthens safety, precision, and eco-friendly practices to boost profits.

Custom Precision parts

Fully custom components engineered to exact specifications. (Precision parts)

Semi-standard parts

Standard base models with customizable adjustment to meet project-specific demands.

Standard parts

Ready-to-use components with standard specs. (Standard parts)

Stage-Specific Automation Solutions

Our solutions align with every project phase—initial, mid, and final—addressing stage-specific challenges to ensure precision parts meet your specs, quality, and budget.

In early automation projects, ambiguous designs, unclear specs, unpredictable costs and supplier doubts make it hard to control cost, timeline, and quality.

Expert Support

-

DFM feedback & optimization

Expert advice for efficient, manufacturable design improvements.

-

Procurement list planning

Expert guidance to choose the best standard components and coordinate bulk procurement.

-

Accurate lead time estimates

Reliable timelines with real-time updates via our online platform.

-

Integrated cost management

Get instant quotes and flexible pricing to validate designs early and control project costs.

In the mid stage of automation projects, extended custom part lead times, inconsistent quality risks, unplanned design changes, and hurdles threaten timelines.

Expert Support

-

Real-time production tracking

Monitor order status 24/7 via online platform or dedicated support.

-

Strict quality control system

Multi-step inspections ensure top quality; fast response for any issues.

-

Rapid design change support

Fast design updates with optimized production scheduling—no extra cost, no delays.

Manufacturing Capabilities

-

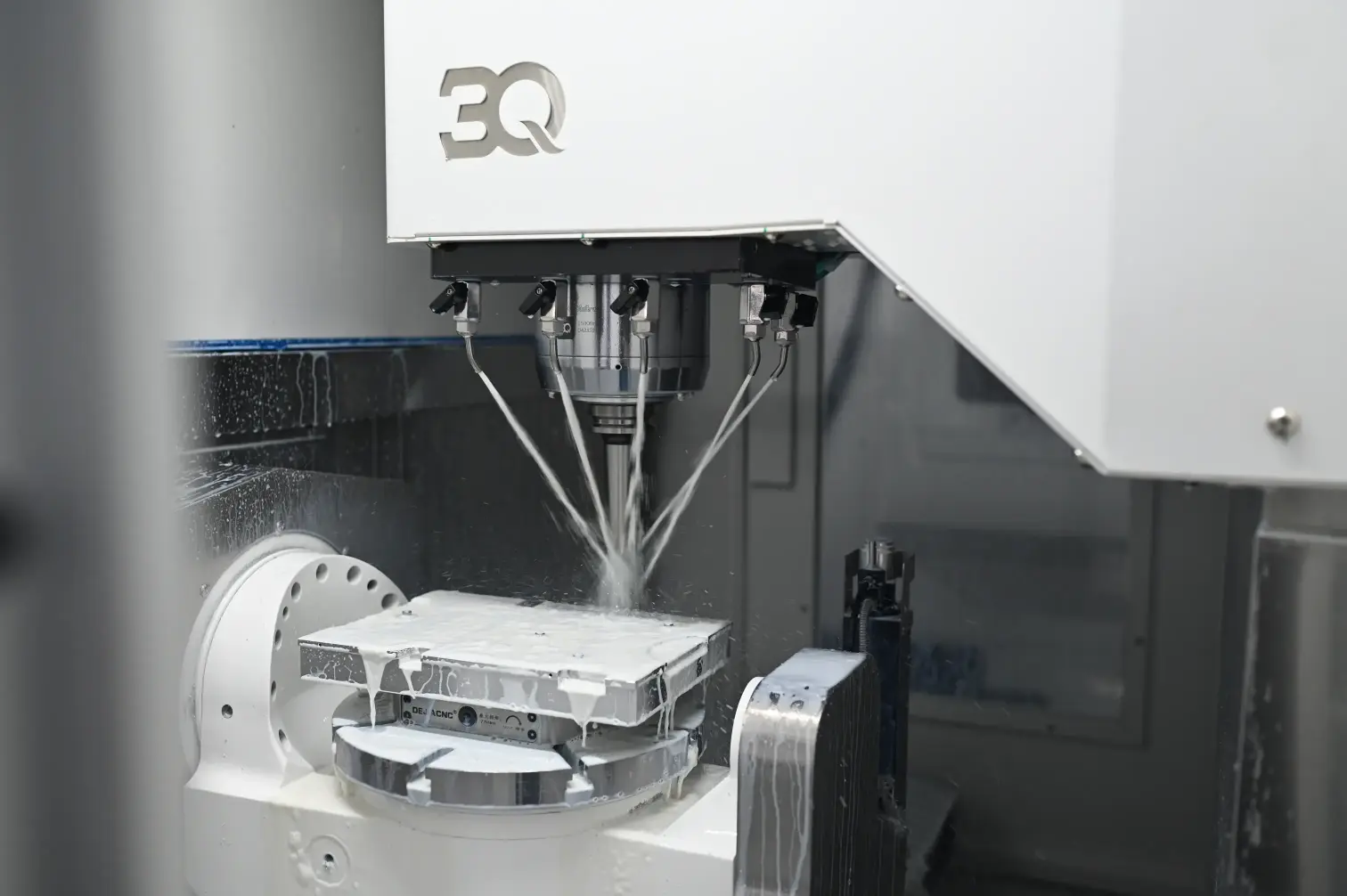

Precision on-demand manufacturing

±0.01mm tolerance for high-performance automation components.

-

Assembly support

One-stop assembly guidance, pre-assembly options, and responsive after-sales help.

In the final stage, execution gaps in procurement plans and unexpected part issues during installation can delay commissioning and impact delivery schedules.

Expert Support

-

Accurate procurement execution

On-time purchasing supported by tracking and quick problem-solving.

-

Fast replacement for missing parts

Parts quickly sourced or made within 1-3 days.

-

Responsive issue handling

Rapid part analysis and redesign to ensure fit, reliability, and performance.

Sourcing for the Automation Parts

We Manufacture Precision Parts.

We specialize in high-precision automation parts designed for tight tolerances and top performance. From EOATs and jigs to gears, shafts, and structural frames, our capabilities support ± 0.01—0.03mm accuracy in critical alignment, handling, and assembly processes.

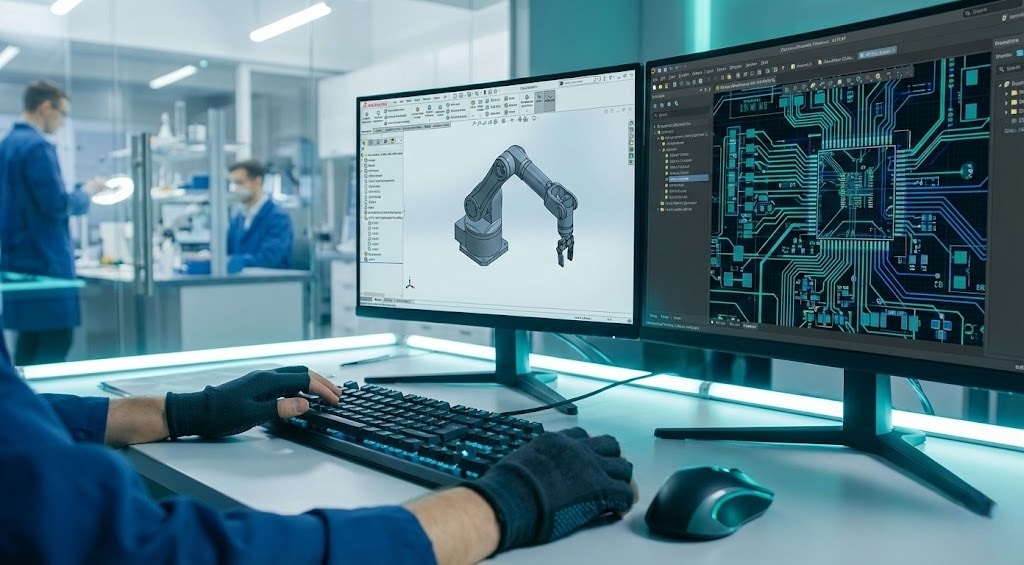

With over 150+ advanced 5-axis CNC machining centers and a team of skilled engineers, we offer both design support and precision manufacturing under one roof. Whether you're working with standard or collaborative robots, we customize components to fit your automation needs.

From one-off prototypes to production runs, we're here to help you build smarter, faster, and more reliable automation systems.

Customization If Required.

Semi-standard components offer ready-to-ship convenience with optional adaptability. We supply base models and modify specifications (length, mounting, material, etc.) to match your project's unique needs.

- Linear motion components

- Pneumatic components

- Transmission parts

- Hydraulic components

- Conveyor systems

- Frame & enclosure parts

- Fasteners

- Motors & drives

- Sensors

- Low-voltage electricals

- Aluminum profiles & accessories

We Source Standard Parts.

We streamline automation projects by procuring standard components according to your BOMs for rapid integration. From guide shafts and sensor cams to valves and pneumatic clamps, we support:

Core ComponentsGuide shafts, robot bodies, valves, linear guides, locating pins, fixtures, jigs, brackets, couplings, shafts, hinges, bushings, seals.

Support SystemsPneumatic/quick clamps, piping fittings, end-of-arm tools, pillars, bases, springs, magnetic products, nitrogen springs, dispensing accessories.

Our Manufacturing Capabilities

Metals

Plastics

*Common materials are shown above. Explore our Material Lists for more.

,清晰展示其.jpg)

。.jpg)

涂层处理的长方形铝板。表面覆盖一.jpg)

表面处理的长方形钢制或铸铁零件。表面呈现深.jpg)

去毛刺处理后的长方形小型金属零件。所有.jpg)

处理的长方形铝合金板。表面呈现.jpg)

标准处理、用于比对的长方.jpg)

Automation Applications

Automation Parts for Cross-Industry Needs

Non-standard fixtures and modules for assembly lines aluminum profiles with anodized finish, ensuring durability in high-frequency use.

Precision components for testing equipment (e.g. Mindray's in-vitro diagnostic modules) focused on flatness (≤0.02mm) for stable operation.

Structural parts for battery production lines - steel components with powder coating to resist corrosion in factory environments.

Lightweight aluminum brackets for robotic arms optimized for low cost and quick turnaround (50+ varieties, 10-50 units/batch).

How Automation Engineers Use DakingsRapid Networks

Clamps

End effectors

Casings

Sensors

Motors

Tubing

Housing & containers

Automation parts

Replacement parts

Parts for

Assemblies

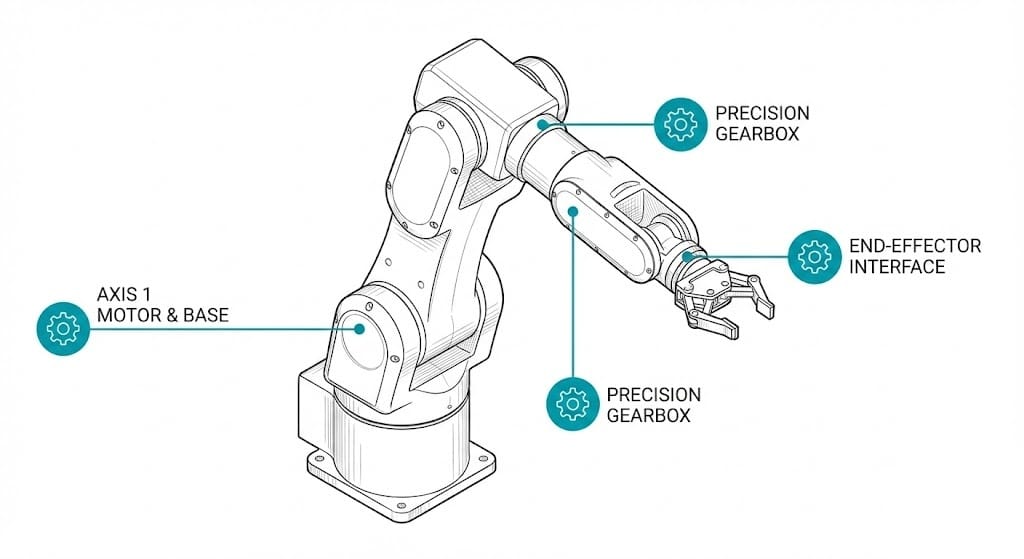

Precision Manufacturing & Assembly for 6-Axis Robots

ChallengeA robotics company needed high-tolerance components for 6-axis robots (under 8 microns) and a streamlined assembly process to slash production time by 25%.

SolutionDakingsrapid delivered an end-to-end solution:

- Custom CNC-machined parts with 5-micron repeatability

- 6-axis robotic cells with auto-alignment for rapid assembly

- Real-time CMM checks during manufacturing and assembly

- AI workflow optimization to eliminate bottlenecks

The integrated solution achieved 99.2% compliant parts with 7-micron assembly accuracy, cut total production time by 28%, and scaled to 5,000 units/month within 10 weeks.