One Team for One Industry!

Every team with 7+ years of deep-dive experiences,solving 96% of processing challenges across their specialized sectors.We provide an agile, meticulously vetted, and expertly managed global supply chain for custom mechanicals, fueled by world-class experts alongside technology.

& DFM

BOM Capabilities

experience

delivery

Certified

Manufacturing Capabilities

CNC Machining

Tight tolerances and finishing capabilities, as fast as 2 days.

Sheet Metal

Experience the versatility & cost efficiency with flexible application options.

Precision Turning

Manufacturing Capabilities to Meet YourNeeds.

3D Printing

FDM, SLS, SLA, MJF technologies.

Surface Treatment

Comprehensive processing: sandblasting, oxidation, electroplating, and coating.

Assembly and welding

Strict quality control and final assembly.

Dakings Rapid

Dakings is a reliable precision manufacturer with over 600+ machines and two factories covering 17,000 square meters. We can provide CNC milling, turning, grinding, sheet metal, 3d printing and advanced surface finishing services without MOQ. With instant quoting, intelligent design for manufacturability feedback, and transparent order tracking, you can make faster, smarter decisions with full visibility and control.

Learn more about our network →

You’re in Good Company

We believe success comes from great customer service and delivering high quality parts, and industry experts agree.

Good comments from Fortune 500 manufacture

Serving global customers, whether it’s high-precision parts or rapid prototyping, we are committed to providing quality that exceeds expectations.

48*******9A

DakingSrapid consistently provides high-precision aluminum components to extremely high quality standards. Their delivery speed is impressive.

Samuel Leuman

23*******7B

The parts are perfect! They followed the drawings and 3D data exactly, without the slightest deviation. A very professional team.

Charles Whitlock

56*******2M

Lavorazione di buona qualità. La finitura superficiale delle parti in acciaio inossidabile era eccellente. La spedizione ha richiesto 2 giorni in più del previsto, ma le parti valevano l'attesa.

Marco Rossi

15*******2X

The printouts were incredibly accurate, perfectly matching my design, and worked flawlessly! Their online quote tool was also very intuitive.

Alex Thompson

89*******1L

As partes funcionais funcionam bem, mas o acabamento estético não ficou exatamente como eu imaginava. Havia algumas marcas visíveis de ferramentas que exigiram polimento manual.

Lucas Mendes

99*******1Q

The parts we ordered arrived ahead of schedule, and the dimensional tolerances were all within the promised range. Secure packaging too.

Todd Harrison

34*******9S

Excelente comunicación por parte del equipo de ingeniería. Uno de los orificios estaba ligeramente apretado, pero aún dentro de los límites de tolerancia. En general, una experiencia muy buena.

Sofia Garcia

33*******8L

An exceptional experience! The tiny nylon parts printed by SLS 3D are critical to our production applications, and the quality is impeccable.

Michael Turner

91*******5R

Very cost-effective solution for our low-volume production run. The anodizing color was slightly different from the sample, but acceptable.

Ravi Patel

77*******5K

Der Kundenservice hat sehr schnell reagiert und alle unsere Fragen während des CNC-Bearbeitungsprozesses geklärt. Sehr empfehlenswert!

Sarah Jung

44*******3F

Du téléchargement des fichiers CAO à la réception des pièces, tout le processus s'est déroulé sans encombre. La qualité du moulage par injection a dépassé nos attentes.

Pierre Laurent

21*******4D

Fast turnaround time and excellent communication. The team helped optimize our design for manufacturing, saving us costs.

David Henderson

65*******2P

The surface finish on the anodized aluminum parts was flawless. Truly professional quality that represents our brand well.

Jessica Miller

98*******7T

We have used several suppliers, but this is by far the most consistent. Dimensions are always spot on.

Thomas Reynolds

42*******8K

Received the order from Dakingsrapid quickly. The parts function correctly, but there were minor cosmetic scratches on the surface. Packaging could be improved.

Robert Kingsley

19*******3B

First time using Dakingsrapid. The pricing is very competitive, but email responses were a bit slow due to timezone differences. Parts are okay for the price.

Kevin Brooks

Major Industries

Dakings specialises in 6 main industries as above, servicing your projects with team specializationsby Industry. These teams not only have in-depth industry knowledge, but also keep abreast ofindustry trends to provide customised solutions to our clients.

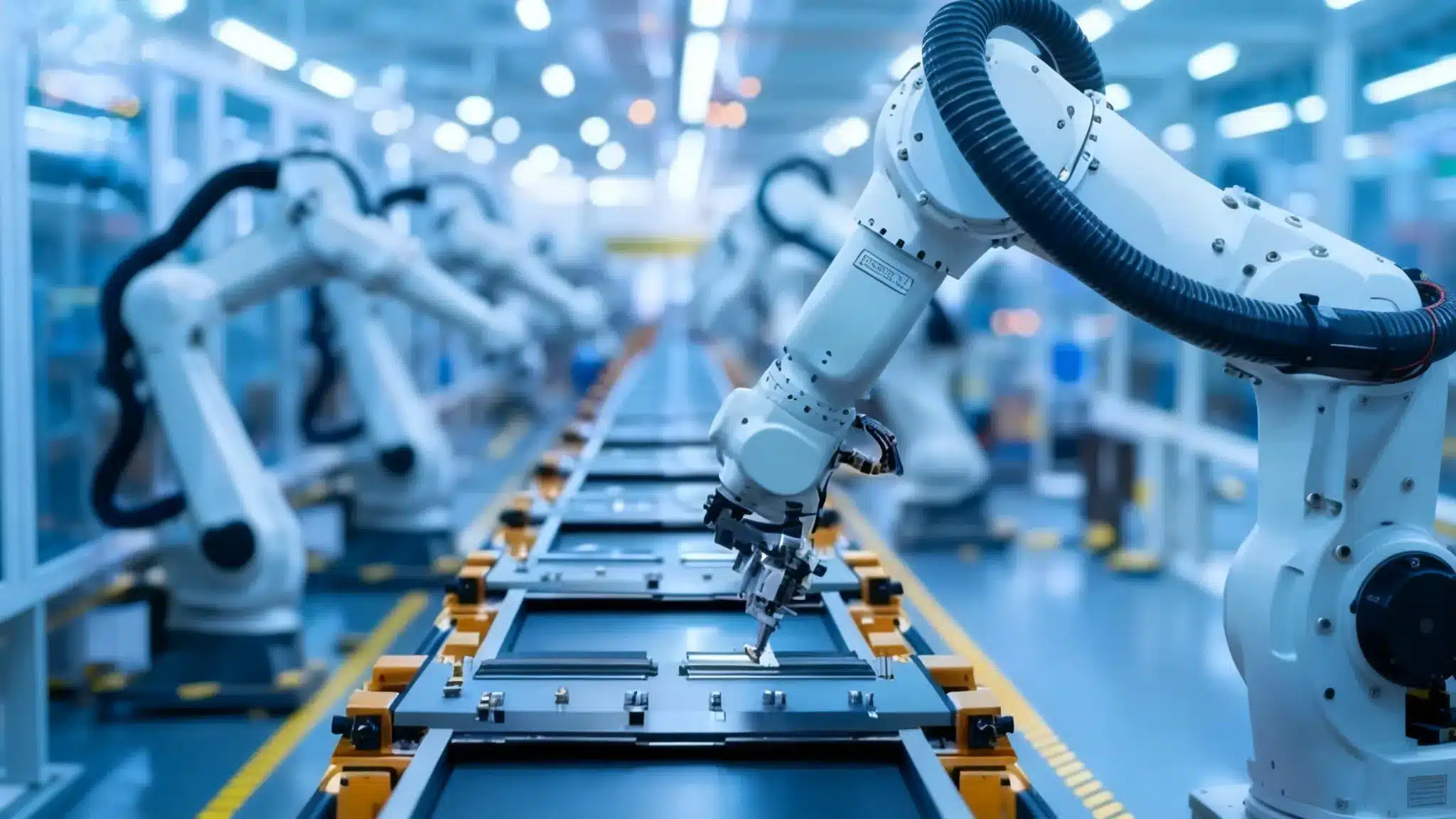

Robotics

From intelligent collaborative arms to autonomous mobile robots, we provide high-precision, high-reliability core components and system integration solutions.

In-depth understanding →

Medical Device

Committed to the innovative research and development of medical imaging, diagnostic instruments and surgical assistance systems, we safeguard life and health through precision manufacturing.

In-depth understanding →

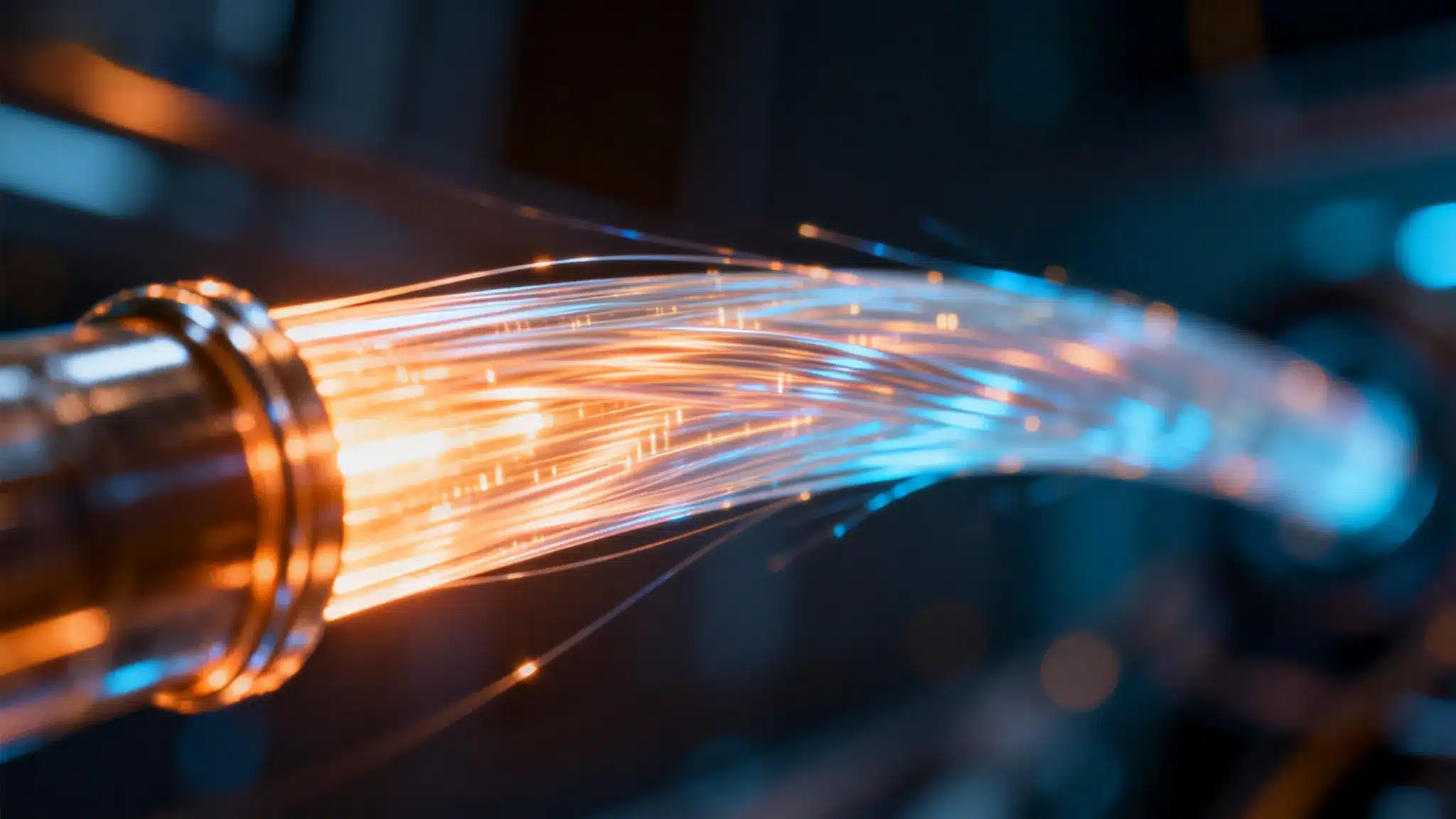

Optical Communictaion

Build the foundation for next-generation high-speed optical networks and provide high-performance solutions from optical modules to core switching equipment.

In-depth understanding →

Automation

Customized Automated Parts: Non-standard solutions for the electronics, medical, and new energy sectors that combine precision and cost-effectiveness – fast, reliable, and competitive.

In-depth understanding →

Automotive

Precision automotive components: Every system embodies superior engineering.

In-depth understanding →

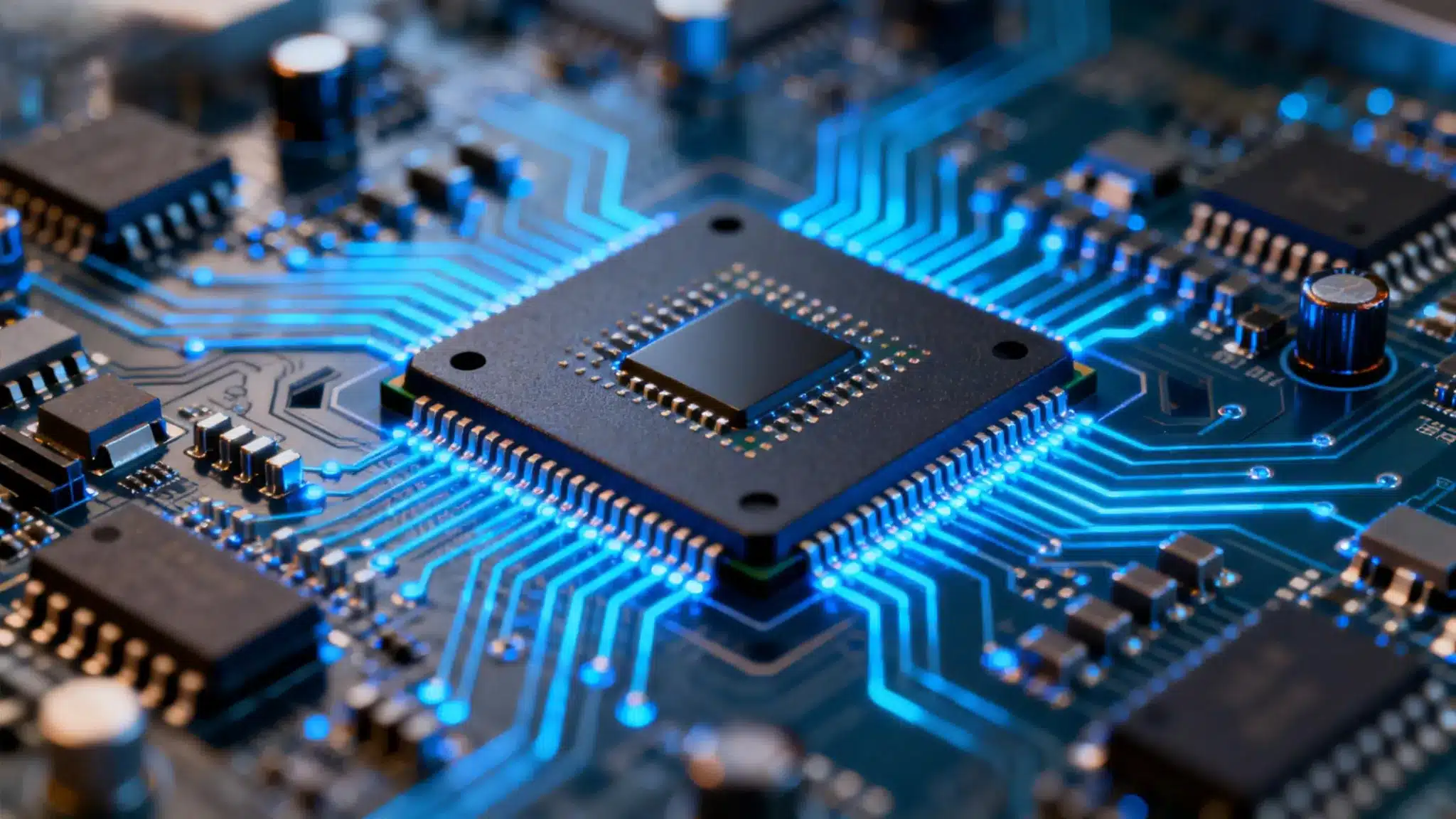

Semiconductor

Precision semiconductor component and part manufacturing: Micron/submicron tolerance solutions for semiconductor equipment, wafer fabrication, and packaging testing.

In-depth understanding →Our Advantages & Services

Dakings Rapid delivers a streamlined, end-to-end project service process for fast and reliable execution.

DakingsRapid has established professional teams for each of the six industries it focuses on, with each team possessing expertise in the technical details of their specific industry and extensive practical experience.

DakingsRapid ISO 9001 / ISO 13485 / ISO 14001 / ISO 16949 certified, with Dun & Bradstreet verification for reliable manufacturing.

DakingsRapid From NDA compliance to internal access control, all client and project data are handled with the highest level of confidentiality.

DakingsRapid Full range of inspection tools (Zeiss & Hexagon CMM, etc.) to assure high precision. Qualification rate: 99.5%.

DakingsRapid A fleet of 577 advanced machines—including DMG MORI, Mazak, JINDIAO, American HARTING lathes, and precision grinders—supports high-efficiency, high-precision machining across complex and high-volume projects.

How can we cooperate?

From design submission to parts delivery, we've streamlined the process into three efficient steps.

Consult Expert Team

Directly communicate with our business specialists. We provide 24/7 online support to discuss your needs immediately.

Get Instant Quote

Our intelligent system provides accurate and competitive pricing in real-time.

Fast Parts Delivery

After rigorous quality inspection, your custom parts are packed securely and shipped via express global logistics.

No hidden fees. Fast response guaranteed.

Customer success stories

We work with partners across automotive, aerospace, medical devices, electronics, industrial machinery, and robotics. From first-time product innovators to global manufacturers, our CNC machining capabilities deliver precision, consistency, and scalable production. Clients around the world rely on us to turn complex designs into high-quality parts with dependable lead times and strict quality control.

Dakings FAQ

-

All efficient production begins with a clear manufacturability insight. After you upload your CAD files, DakingsRapid’s platform immediately launches its built-in DFM analysis engine, automatically scanning key geometric features, wall thicknesses, support structures, and tolerance feasibility. It returns visual feedback within seconds, clearly identifying potential risk points. For projects with complex structures or stringent precision requirements, our engineering team will provide a human DFM review within one business day, offering optimization suggestions based on data, including design improvements, process path selection, and material matching. By assessing manufacturability in advance, you can reduce rework risks, shorten lead times, and allow your design to smoothly transition to mass production. Upload your CAD files now for instant analysis, or submit for “Engineer Review” for more in-depth technical advice.

-

Actual production cycles vary depending on part structure, quantity, and chosen manufacturing method. Generally, rapid prototyping projects such as CNC machining or 3D printing can be completed and shipped within 4–6 business days; while injection molding, small-batch production, or projects with more complex processes typically have an overall cycle of 3–5 weeks. If you require a more accurate lead time forecast, simply provide your 3D/2D drawings, material requirements, and estimated quantity. After submission, the platform will automatically provide the corresponding production cycle during the quotation stage to help you better plan your project schedule.

-

DakingsRapid offers a variety of appearance and performance enhancement solutions for metal and plastic parts, including anodizing, powder coating, painting, electroplating, wire drawing, sandblasting, and polishing. We support custom resin finishes and can also color according to RAL/Pantone color codes, easily meeting brand color requirements. For projects requiring a uniform appearance, we can also perform color consistency and gloss testing to ensure that parts from different batches maintain the same visual effect. For more information on our processing methods and finished product examples, please visit our “Surface Finishes” and “Materials” pages.

-

According to your requirements, we can provide various quality and compliance documents, including factory inspection reports, RoHS/REACH environmental compliance certificates, and third-party inspection data. For parts requiring high precision, we can also provide dimensional measurement data, CMM coordinate measuring machine reports, and First Article Inspection (FAI) documents with each order to ensure that every batch of products meets your engineering specifications.

-

The main materials we use—such as various types of aluminum, stainless steel, and common engineering plastics—generally meet RoHS and REACH environmental regulations. If needed, we can provide compliance certificates issued by our material suppliers or commission relevant testing reports from third-party organizations to ensure that the materials meet the target standards. When submitting a quotation or placing an order, please specify the specific requirements you wish to meet (such as RoHS 3, REACH SVHC list, etc.) so that we can verify the materials in advance.

-

Here, every product undergoes a rigorous quality verification process before shipment—from small-batch trial production and functional and dimensional testing to final customer confirmation. We consistently ensure that all parts meet agreed specifications before delivery, minimizing the loss of any defective products. With stability, precision, and reliability at our core, the status of each batch is jointly overseen by our engineering team and the customer. In the rare case of discrepancies with the agreement, we handle it according to a clear and transparent after-sales process. Customers simply need to submit a quality complaint and provide relevant supporting documentation, such as test data, photos, or videos, so that we can accurately determine the problem. Our quality team typically completes a review within 48 hours, analyzing the root cause, and providing a clear explanation regardless of whether the problem originates from design, processing, materials, or transportation. After the assessment, we will provide a reasonable solution based on the order terms, such as rework, remanufacturing, partial refund, or issuance of an equivalent credit line. Every case is documented, and complete testing and handling reports are maintained to ensure traceability. To expedite the process, we recommend that customers retain original samples and all supporting documentation. All feedback will be incorporated into our continuous improvement system to drive continuous improvement in overall processing quality and service experience.