One Team for One Industry!

Transform your idea into a market-ready product—faster, smarter, effortlessly.

Each of our teams possesses over 7 years of in-depth research experience and is capable of solving 97% of the processing challenges in their respective fields.

DakingsRapid NPI Solutions

We support projects from conceptual design and small-batch prototype development to large-scale production.

Design & Engineering

Turn concepts into precision-engineered products with DakingsRapid end-to-end expertise.

Verification Phase

De-risk production with rigorous prototyping, testing, and manufacturability validation.

Mass Production

Seamlessly scale validated prototypes into high-volume production with optimized processes and materials.

DakingsRapid NPI production process

From product development to production, we ensure every step of the manufacturing process meets strict ISO9001 quality standards and aligns with our company’s Production Part Approval Process (PPAP)

DakingsRapid Raw Material Quality Management

All raw materials used by DakingsRapid undergo rigorous procurement review and incoming inspection to ensure a stable production foundation.

Quality Certificate

Only purchase from famous raw material supplier

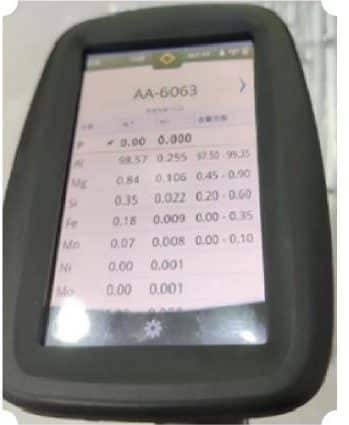

Spectrometer

Spectrometer detects raw materials

Inspection Report

Third party testing and verification materials

Four key areas of support provided by DakingsRapid

We customize support for clients across various industries in the following four key professional areas. We ensure that each stage is handled by professionals with expertise in the specific industry.

Production Control Support

- Will control all the production process

- From raw material to programming and machining.

Technical Support

- 3 engineers will provide technical services only for you.

- Provide suitable solutions based on technical difficulties

Quality Control Support

- Qualify pre-production sample

- Doing inline inspection

- Inspect finished goods

Order Follow-up Support

- One production merchandiser

- Will follow the production progress to inspection processing every day

DakingsRapid Quality Management

Industry-specific QC teams conduct inspections from production to pre-shipment, ensuring consistency and delivery reliability.

Compliance

- Company certification

- Law and regulation updates

- 2 engineers

Testing

- Execute chemical requirements

- Solve test issues

- 2 engineers

QA

- Qualify pre-production sample

- Doing inline inspection

- 2 engineers

Inspection

- Inspect raw material

- Inspect finished goods

- 4 QCs

Rigorous Control for Assured Product Excellence

Our quality assurance department utilizes state-of-the-art testing equipment and adheres to a stringent inspection protocol. Each product undergoes comprehensive checks at various stages, from raw material to finished goods, ensuring traceability and accountability.

inspect material

the mistake at early process

ordered)--➤ OQC report

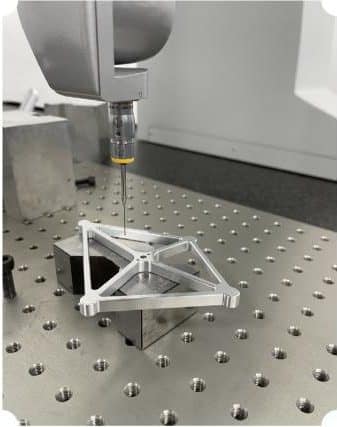

DakingsRapid Precision Inspection Equipment

Dakings has a full range of inspection tools and equipments to assure your high precision tolerances and geometric tolerances, such as Zeiss & Hexagon CMM measurement equipments, Marr and Mitsutoyo inspection toolings.

Our qualification rate is 99.5%

DakingsRapid's five specific tests

Material Detection

Spectrometer to verify the material composition meets the specified requirements.

Visual Inspection

The surface should be free of defects such as scratches, unevenness, or burrs, ensuring a high-quality finish.

Dimension Measurement

Parts must adhere to the dimensional tolerance requirements specified in the drawings.

Functionality

After assembly, the parts must perform their intended function effectively.

Physical Properties

Inspect key physical properties as required to ensure they meet the necessary standards.

Integrated Manufacturing System

Dakings Rapid delivers a streamlined, end-to-end project service process for fast and reliable execution.

DakingsRapid has established professional teams for each of the six industries it focuses on, with each team possessing expertise in the technical details of their specific industry and extensive practical experience.

DakingsRapid ISO 9001 / ISO 13485 / ISO 14001 / ISO 16949 certified, with Dun & Bradstreet verification for reliable manufacturing.

DakingsRapid From NDA compliance to internal access control, all client and project data are handled with the highest level of confidentiality.

DakingsRapid A fleet of 577 advanced machines—including DMG MORI, Mazak, JINDIAO, American HARTING lathes, and precision grinders—supports high-efficiency, high-precision machining across complex and high-volume projects.

How can we cooperate?

From design submission to parts delivery, we've streamlined the process into three efficient steps.

Consult Expert Team

Directly communicate with our business specialists. We provide 24/7 online support to discuss your needs immediately.

Get Instant Quote

Our intelligent system provides accurate and competitive pricing in real-time.

Fast Parts Delivery

After rigorous quality inspection, your custom parts are packed securely and shipped via express global logistics.

No hidden fees. Fast response guaranteed.