Understanding Duplex Stainless Steel: The Stronger, Smarter Alloy

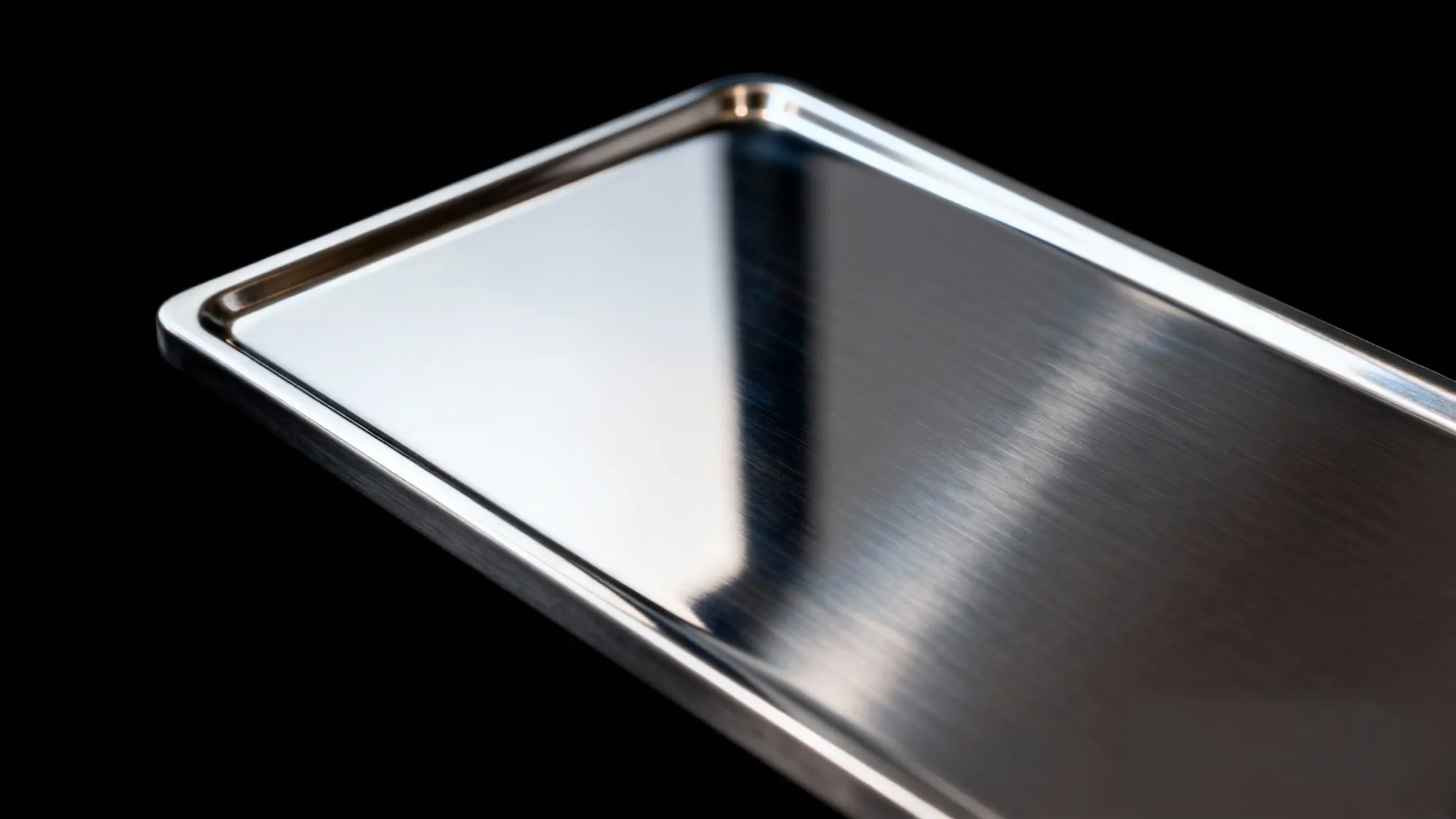

Within the diverse family of stainless steels, duplex stainless steel occupies a unique position. It’s not just another type of steel; it’s a hybrid material designed to address specific limitations of standard 304 and 316 stainless steels.

What is "Duplex"? The Science Behind the Name

The term “Duplex” refers to the material’s two-phase microstructure. Unlike standard stainless steels, which are either fully austenitic or fully ferritic, Duplex stainless steel is engineered to be a perfect mix of both—approximately 50% austenite and 50% ferrite.

This “best of both worlds” structure gives the alloy a distinct advantage:

From the Ferritic side: It gains high strength and resistance to stress corrosion cracking.

From the Austenitic side: It gains ductility and general corrosion resistance.

The Three Key Advantages

1. Superior Strength (Do More with Less)

Duplex stainless steel is roughly twice as strong as standard austenitic grades like 304L or 316L.

Engineering Impact: This high yield strength allows designers to reduce the wall thickness of tanks and pipes. Less material means lighter weight and lower overall material costs, without sacrificing safety.

2. Resistance to Stress Corrosion Cracking (SCC)

Standard stainless steels are vulnerable to Stress Corrosion Cracking—a dangerous failure mode that occurs in chloride-rich environments (like warm saltwater or swimming pools) under tensile stress.

The Solution: The ferritic grain structure in Duplex acts as a barrier, making it virtually immune to SCC where standard steels would fail.

3. Price Stability

Austenitic steels rely heavily on Nickel to stabilize their structure. Nickel prices are historically volatile.

Cost Efficiency: Duplex grades generally use less Nickel (substituting it with Nitrogen for strength), making them a more price-stable option for long-term projects.

Common Grades and Categories

Understanding Duplex means navigating its three main sub-categories:

Lean Duplex (e.g., S32101, S32304):

Use Case: A cost-effective alternative to 304L/316L. Ideal for structural applications like bridges or storage tanks where high strength is needed but extreme corrosion resistance is not.

Standard Duplex (e.g., 2205 / S31803):

Use Case: The “workhorse” grade. It offers superior corrosion resistance to 316L and is widely used in chemical processing, piping, and marine environments.

Super Duplex (e.g., 2507 / S32750):

Use Case: Designed for the most aggressive environments. With a high Pitting Resistance Equivalent Number (PREN > 40), it is used in offshore oil platforms, desalination plants, and subsea risers.

When NOT to Use Duplex (Expert Note)

While powerful, Duplex has an “Achilles’ heel”: Temperature. It is susceptible to embrittlement at extreme temperatures. It is generally not recommended for use above 300°C (572°F) or below -50°C (-58°F). For cryogenic or high-heat applications, standard Austenitic grades remain the safer choice.

Comparing Duplex 2205 with Other Grades

Duplex 2205 is commonly compared with grades such as 304, 316, 904L, Super Duplex (e.g., 2507), and Carbon Steel.

| Grade | Strength | Corrosion | Cost | Weldability | Nickel % | Durability |

|---|---|---|---|---|---|---|

| Duplex 2205 | High | Excellent | Moderate | Good | Lower | High |

| 304 | Moderate | Moderate | Low | Excellent | Higher | Moderate |

| 316 | Moderate | Good | Higher | Excellent | Higher | Moderate |

| 904L | Low | Very High | Very High | Moderate | Very High | High |

| Super Duplex | Very High | Excellent | High | Good | Lower | Very High |

| Carbon Steel | Low | Poor | Very Low | Excellent | None | Low |

The Engineering Advantage: Mechanical Properties of Duplex Stainless Steel

Duplex stainless steel is not merely an alternative to standard grades; it is a high-performance hybrid. By maintaining a balanced “dual-phase” microstructure—approximately 50% ferrite and 50% austenite—this alloy delivers a unique combination of strength and resilience that outperforms traditional 300-series stainless steels.

1. High Strength Characteristics: The “Lightweighting” Advantage

The most defining mechanical property of Duplex stainless steel is its yield strength, which is typically two times higher than that of standard austenitic grades (like 304L or 316L).

Structural Efficiency: This superior strength allows engineers to design with thinner wall thicknesses.

Cost & Weight Reduction: By reducing the material gauge, you decrease the total weight of the structure (crucial for transport tanks) and lower material costs, all without compromising performance or safety.

2. Unrivaled Corrosion Resistance

While standard stainless steels struggle in aggressive environments, Duplex excels. Its complex chemical composition provides a multi-layered defense against degradation.

Pitting and Crevice Corrosion: Thanks to high levels of Chromium, Molybdenum, and Nitrogen, Duplex grades achieve a high Pitting Resistance Equivalent Number (PREN). This makes them exceptionally resistant to localized corrosion in chloride-rich environments like seawater, brine, and bleaching operations.

Stress Corrosion Cracking (SCC): Standard austenitic steels are prone to cracking under tensile stress in hot chloride solutions. The ferritic phase in Duplex provides inherent immunity to SCC, making it the preferred choice for offshore oil & gas platforms and desalination plants.

Acidic Environments: It offers robust resistance against sulfuric and hydrochloric acids, ensuring reliability in chemical processing and wastewater treatment applications.

3. The Science Behind the Strength: Chemical Composition

The mechanical superiority of Duplex is directly derived from its precise alloying elements. It is not just about the ingredients, but how they interact:

Chromium (Cr): The backbone of corrosion resistance. Duplex grades typically contain higher chromium (20-28%) than standard grades.

Molybdenum (Mo): Works in synergy with chromium to prevent pitting and crevice corrosion.

Nitrogen (N): The critical “strength booster.” Nitrogen significantly increases tensile strength and yield strength while simultaneously enhancing resistance to pitting.

Nickel (Ni): Stabilizes the austenitic phase to ensure the correct 50/50 balance, providing toughness and ductility.

Where is Duplex Stainless Steel Used?

Dominance in Oil & Gas

Why: Combines extreme strength with resistance to sour gas and saltwater.

Where: Subsea flowlines, offshore platforms, umbilicals, and heat exchangers.

Benefit: Reduces the risk of Stress Corrosion Cracking (SCC) and lowers lifecycle maintenance costs.

Key Industrial Sectors

Desalination: Essential for handling high-pressure saline water in Reverse Osmosis systems.

Chemical Processing: Used in tanks and pressure vessels handling aggressive chlorides and acids.

Pulp & Paper: Provides durability in corrosive bleaching environments.

Emerging Technologies

Green Energy: Critical for offshore wind turbine components and tidal energy systems.

Hydrogen: High-pressure storage solutions for the clean energy transition.

3D Printing: Enabling complex, low-waste component manufacturing.

Manufacturing Excellence: The Production of Duplex Stainless Steel

Producing high-quality Duplex Stainless Steel is a precise metallurgical balancing act. Unlike standard grades, the manufacturing process—from alloying to final heat treatment—must be tightly controlled to achieve the signature 50/50 dual-phase microstructure (Austenite/Ferrite).

1. Raw Material Selection & Alloying Strategy

The performance of Duplex steel begins with the purity of the raw materials. We select high-grade elements to balance corrosion resistance with mechanical ductility:

- Chromium (Cr): The primary ferrite-former. It provides the base corrosion resistance.

- Nickel (Ni): The essential austenite-former. It enhances toughness and fabricability.

- Molybdenum (Mo): Critical for preventing localized corrosion (pitting) in chloride environments.

- Nitrogen (N): A potent interstitial strengthener. It increases yield strength and promotes austenite formation, allowing the material to stretch without breaking.

2. Fabrication and Welding Protocols

Welding Duplex stainless steel requires specific heat-input controls to prevent phase imbalance.

- Methods: We utilize TIG (GTAW) or MIG (GMAW) processes.

- Filler Metals: We typically use filler metals with slightly higher Nickel content (over-alloyed) to promote austenite formation in the weld zone.

- Heat Control: Strict control of interpass temperature is vital. Excessive heat can precipitate detrimental intermetallic phases (like the Sigma Phase), while too little heat can lead to nitride precipitation, both of which ruin corrosion resistance.

3. Critical Heat Treatment: Solution Annealing

The "reset button" for the material's properties is the Solution Annealing process.

- The Process: The steel is heated to 1,020°C – 1,100°C (1,870°F – 2,010°F) to dissolve any unwanted precipitates.

- The Quench: It is then rapidly cooled (water quenched). This rapid cooling "freezes" the microstructure in its ideal state.

- The Danger Zone: We strictly avoid prolonged exposure in the 600°C – 950°C range, as this causes the formation of brittle intermetallic phases that destroy toughness.

4. Microstructure Analysis & Quality Assurance

The final validation is microscopic.

- The Goal: A near-perfect 50/50 ratio of Austenite (for toughness) and Ferrite (for strength).

- The Inspection: Using ASTM standard test methods, we verify that there are no "lean" zones or unwanted precipitates. This ensures the material will perform reliably in subsea, chemical, or oil & gas applications.

Mastering Duplex Stainless Steel: Selection, Fabrication, and Maintenance

Duplex Stainless Steel offers an exceptional balance of strength and corrosion resistance, but unlocking its full potential requires adherence to strict protocols. From alloy selection to lifecycle maintenance, every step determines the longevity of your components.

1. Selection Criteria: How to Choose the Right Grade

Before specifying a material, evaluate the operational environment against these five critical factors:

Corrosion Resistance (PREN): Do not just ask for “stainless.” Assess the specific environment—chloride concentration, pH levels, and H2S presence. Ensure the grade’s Pitting Resistance Equivalent Number (PREN) matches the severity of the corrosive media.

Thermal Limits: Unlike austenitic steel, Duplex has strict temperature windows. It is generally suitable for temperatures between -50°C and 300°C. Avoid applications exceeding 300°C to prevent “475°C embrittlement.”

Mechanical Load: Calculate the required yield strength. Duplex’s high strength often allows for thinner wall sections, reducing weight and material costs in pressure vessels.

Weldability Profile: Consider the complexity of fabrication. While Duplex is weldable, it requires tight control over heat input. Ensure your fabrication partner has the capability to maintain the phase balance during welding.

Total Cost of Ownership (TCO): Look beyond the price per kilogram. A slightly more expensive Duplex grade may allow for a lighter design and longer service life, offering better long-term economy than a cheaper austenitic alternative.

2. Fabrication Best Practices: Handling and Welding

The integrity of Duplex steel can be compromised before it even enters service if mishandled.

Preventing Iron Contamination: Always use dedicated tools (brushes, grinding discs) that have never touched carbon steel. Iron particles embedded in the surface will rust and initiate pitting.

Welding Controls:

Preheat Caution: Unlike carbon steel, Duplex rarely requires high preheat. Instead, focus on strict interpass temperature controls (typically max 150°C) to prevent the formation of detrimental intermetallic phases.

Heat Input: Use controlled heat to allow sufficient time for austenite reformation in the heat-affected zone (HAZ).

Storage: Store materials off the ground, covered, and separated from carbon steels to prevent galvanic corrosion.

3. Lifecycle Management: Maintenance and Care

To ensure decades of service, implement a proactive maintenance strategy.

Routine Cleaning: Regularly wash surfaces to remove salt and chloride deposits. Use non-abrasive cleaners to protect the passive oxide layer.

Passivation: Over time, the protective chromium oxide layer may degrade. Periodic chemical passivation (using citric or nitric acid based solutions) regenerates this shield, restoring corrosion resistance.

Inspection Protocols: Schedule regular inspections for “crevice corrosion” in tight joints and welds. Early detection of surface discoloration allows for spot repairs before structural damage occurs.

Qualified Repairs: Any field modifications, especially welding, must be performed by qualified technicians using approved procedures (WPS) to ensure the microstructure is not compromised.

Reference Sources

- Duplex Stainless Steels – An Overview – A comprehensive overview of duplex stainless steels, including their development and optimization.

- Duplex Stainless Steels— Alloys for the 21st Century – A paper discussing the widespread use of duplex stainless steels in various industries and their advantages.

- Super Duplex Stainless Steels – A study focusing on the mechanical and corrosion-resistant properties of super duplex stainless steels.

- Duplex Stainless Steels – A detailed book covering the mechanical behavior and applications of duplex stainless steels.

- Stainless Steel CNC Machining Services

Frequently Asked Questions: Understanding Duplex Stainless Steel

❓ What is Duplex Stainless Steel and how does it differ from 304/316?

Duplex stainless steel is a unique “hybrid” alloy featuring a microstructure of roughly 50% ferritic and 50% austenitic phases.

The Difference: unlike conventional austenitic grades (such as 304 and 316), Duplex offers double the yield strength and significantly superior resistance to stress corrosion cracking.

Cost Advantage: Because Duplex achieves its properties using higher Nitrogen levels rather than high Nickel content, it is often more price-stable and cost-effective than high-alloy austenitic grades.

❓ What are the main types of Duplex, and why is Grade 2205 so popular?

Duplex alloys are categorized into three families based on their alloy content:

Lean Duplex: Cost-effective, used for structural applications.

Standard Duplex (Grade 2205): The “workhorse” of the industry.

Super Duplex: Designed for extreme environments.

Why 2205? Grade 2205 (UNS S31803/S32205) is the most widely used because it hits the “sweet spot” of performance. It offers high resistance to chloride pitting and stress corrosion cracking (SCC), combined with excellent fatigue strength, making it the standard choice for chemical processing and marine environments.

❓ Why is Duplex superior to common steel in corrosive environments?

The superiority of Duplex comes from its chemistry and its structure.

The Chemistry: Precise additions of Chromium, Molybdenum, and Nitrogen give Duplex a high Pitting Resistance Equivalent Number (PREN). This chemical shield prevents localized corrosion (pitting) in chloride-rich settings.

The Structure: The dual-phase microstructure acts as a mechanical barrier. While the austenitic phase provides general corrosion resistance, the ferritic phase provides immunity to Stress Corrosion Cracking (SCC), a common failure mode for standard steels in hot, salty environments.

❓ How is Duplex used in the Oil & Gas industry?

Duplex stainless steels are indispensable in offshore drilling and subsea production due to their ability to withstand “sour service” (hydrogen sulfide) and high-pressure saline environments.

Durability: High PREN grades (like Super Duplex) prevent pitting in seawater and brine.

Weight Reduction: Because Duplex is so strong, engineers can use thinner walls for piping, risers, and subsea manifolds. This reduces the overall weight of offshore platforms, leading to massive savings in construction and logistics costs.

❓ How does the Ferritic/Austenitic balance create high strength?

The “Duplex” advantage comes from the synergy of its two phases:

Ferrite Phase: Provides high yield strength and resistance to stress cracking.

Austenite Phase: Provides ductility and toughness (preventing the metal from being brittle). The Result: A material that is roughly twice as strong as 304/316 stainless steel but retains good weldability and formability. This allows designers to build lighter, stronger, and more durable components.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.