3D Printing – Precision Prototypes & Parts

From concept to functional part in just one day – we offer a variety of options including SLA, SLS, FDM, and metal 3D printing.

as fast as 24 hours

and finishing options

prototype to production

Why Dakings Rapid for 3D Printing

Rapid prototyping and low-volume production, fast and flexible.

-

45+ Materials & Finishing Options

-

Minimum order quantity: one piece.

-

5 Additive Technologies (MJF, SLS, SLA, FDM, Carbon DLS™)

-

High-Fidelity Prototypes for Testing & Fit Checks

-

Dakings Rapid-Verified Quality & Inspection Reports

-

Material Certifications & CoCs Available

-

Instant Quotes & Online Order Tracking

Our 3D Printing Processes

FDM

Thermoplastic filament is extruded layer by layer. Low cost, fast, suitable for basic functional prototypes and fixtures.

SLA

UV laser cures liquid resin. High precision and smooth surface, ideal for appearance models and fine details.

SLS / MJF

Powder-based nylon printing without supports. Strong, isotropic parts for functional prototypes and small-batch production.

SLM

Laser fully melts metal powder. High-strength metal parts for aerospace, medical, and industrial applications.

SLA (Stereolithography)

Key Features

1Cost & Surface: High cost-effectiveness with a smooth surface, suitable for sanding, polishing, and direct or post painting. 2Applications: Ideal for prototyping, sample production, and basic structural and appearance validation. 3Thermal & Accuracy: Heat deflection temperature 60°C (9400 material); standard accuracy ±0.1 mm, optional ±0.05 mm, tolerance up to 0.1%. 4Hardness: Material hardness 85 Shore D.

High Impact Resistance

1Material Characteristics: Greenish-yellow appearance with high toughness and heat resistance; smooth surface suitable for sanding and painting, or direct painting. 2Applications: Commonly used for model assembly trials, screw fastening, snap-fit testing, and products requiring good toughness. 3Thermal & Accuracy: Heat deflection temperature up to 80°C; standard accuracy ±0.1 mm, optional ±0.05 mm printing setting, tolerance up to 0.1%. 4Hardness: Material hardness 85 Shore D.

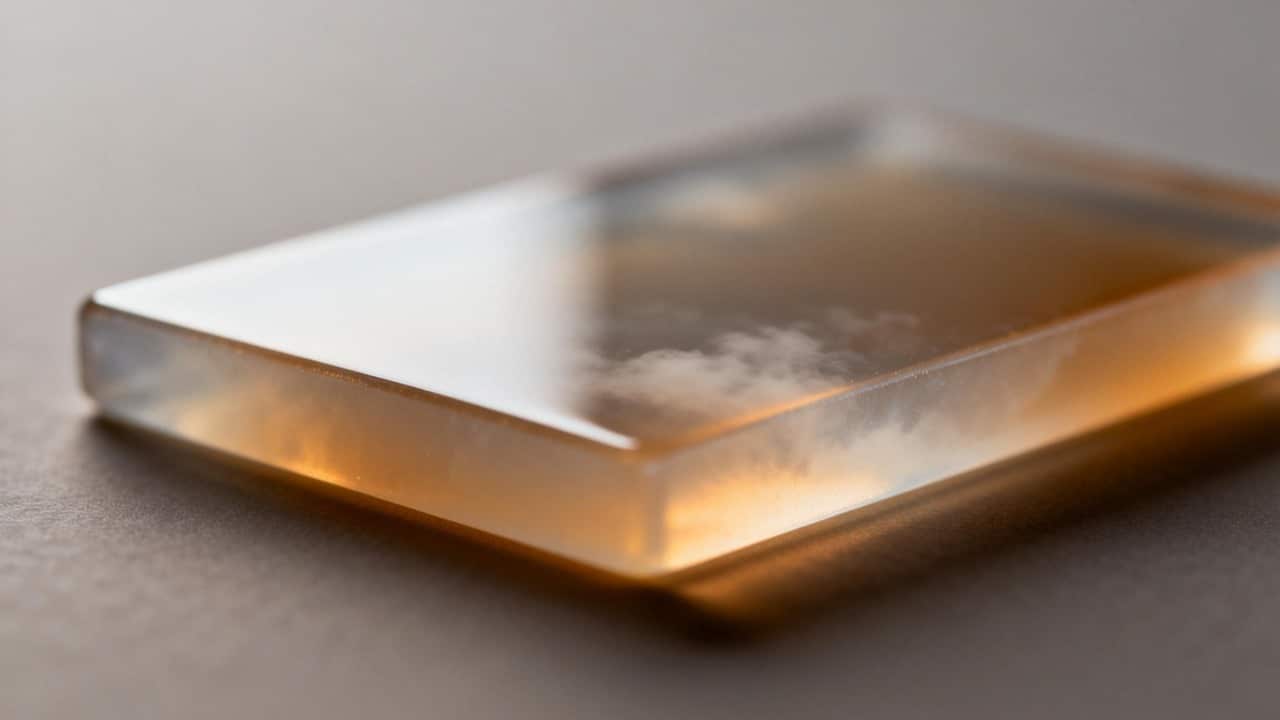

Semi-Transparent

1Surface & Appearance: Smooth surface with high transparency; can be polished to near-glass clarity and dyed in multiple colors. 2Applications: Widely used for parts with high surface-finish requirements, light covers, and applications requiring internal structure visibility. 3Thermal & Accuracy: Heat resistance up to 46°C; accuracy ±0.1 mm with tolerances up to 0.1%. 4Hardness: Material hardness 85 Shore D.

Glass-Like Clarity

1Surface & Transparency: Smooth surface with high transparency; can be polished to near-glass clarity and dyed in multiple colors. 2Applications: Commonly used for parts with high surface-finish requirements, light covers, and applications requiring internal structure visibility. 3Thermal & Accuracy: Heat resistance up to 46°C; accuracy ±0.1 mm, with tolerances up to 0.1%. 4Hardness: Material hardness 85 Shore D.

Premium Black Finish

1Smooth surface, often used for model trial assembly, screw fitting, and snap‑fit testing. 2Can be sanded and polished before painting, or painted directly. 3Good toughness and heat resistance; black tough resin offers excellent overall performance among resin materials. 4Heat resistance: 70°C; accuracy: +0.1mm; tolerance: 0.1% (one‑thousandth).

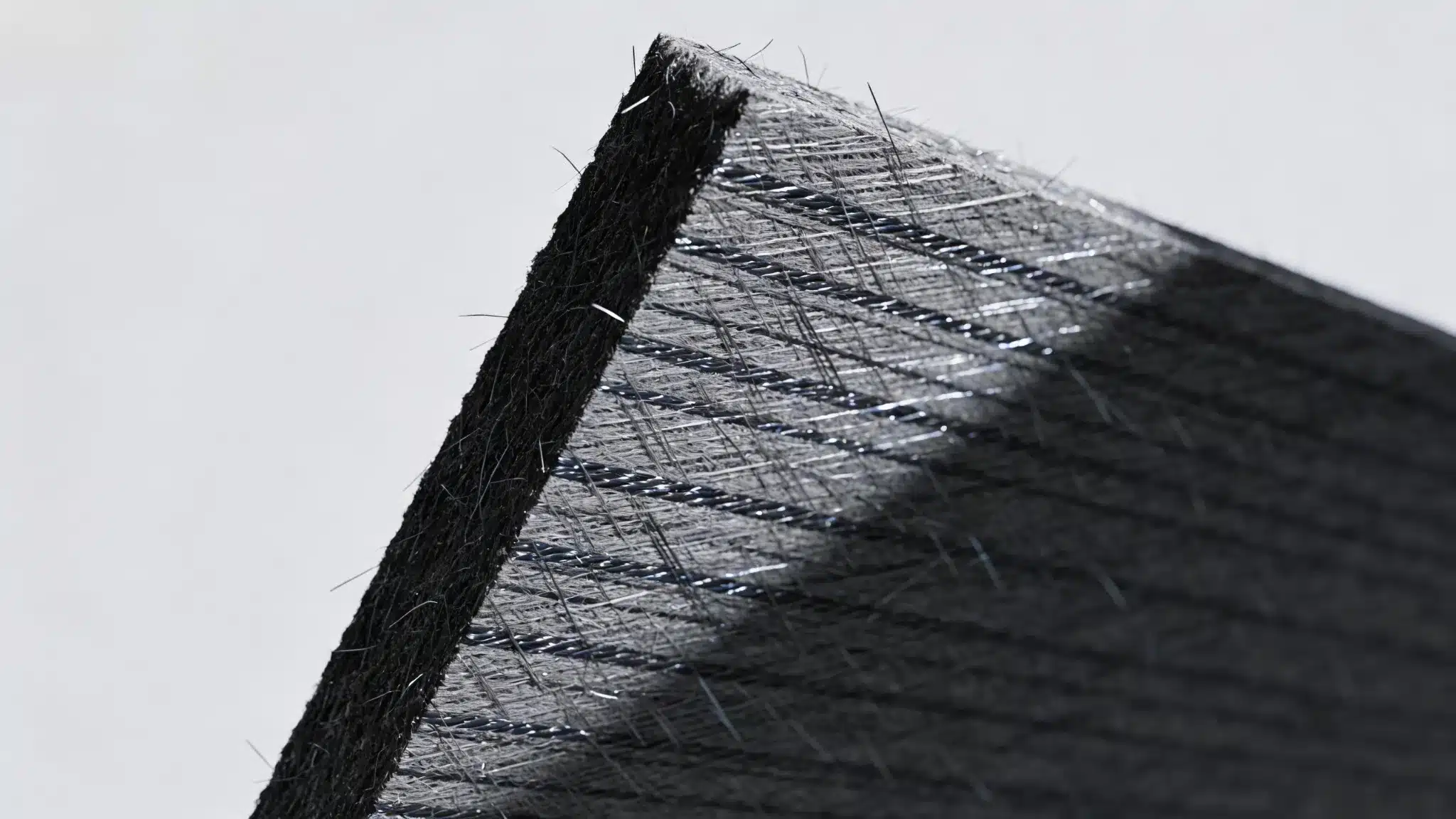

SLS (Selective Laser Sintering)

Material Properties

1Nylon material provides high strength, good toughness, and heat resistance up to 150°C. Suitable for functional testing prototypes and end-use product components. 2Heat resistance: 150°C; dimensional accuracy: ±0.15 mm; tolerance: 0.2% (two-thousandths); hardness: 85 Shore D. 3Widely used in medical devices, automotive parts, aerospace, home appliances, and related fields.

Aesthetic & Functional

1Nylon material provides high strength, good toughness, and heat resistance up to 150°C. Suitable for functional testing prototypes and end-use product components. 2Heat resistance: 150°C; dimensional accuracy: ±0.15 mm; tolerance: 0.2% (two-thousandths); hardness: 85 Shore D. 3Widely used in medical devices, automotive parts, aerospace, home appliances, and related fields.

High Performance

1Nylon material provides high strength, good toughness, and heat resistance up to 150°C. Suitable for functional testing prototypes and end-use product components. 2Heat resistance: 150°C; dimensional accuracy: ±0.15 mm; tolerance: 0.2% (two-thousandths); hardness: 85 Shore D. 3Widely used in medical devices, automotive parts, aerospace, home appliances, and related fields.

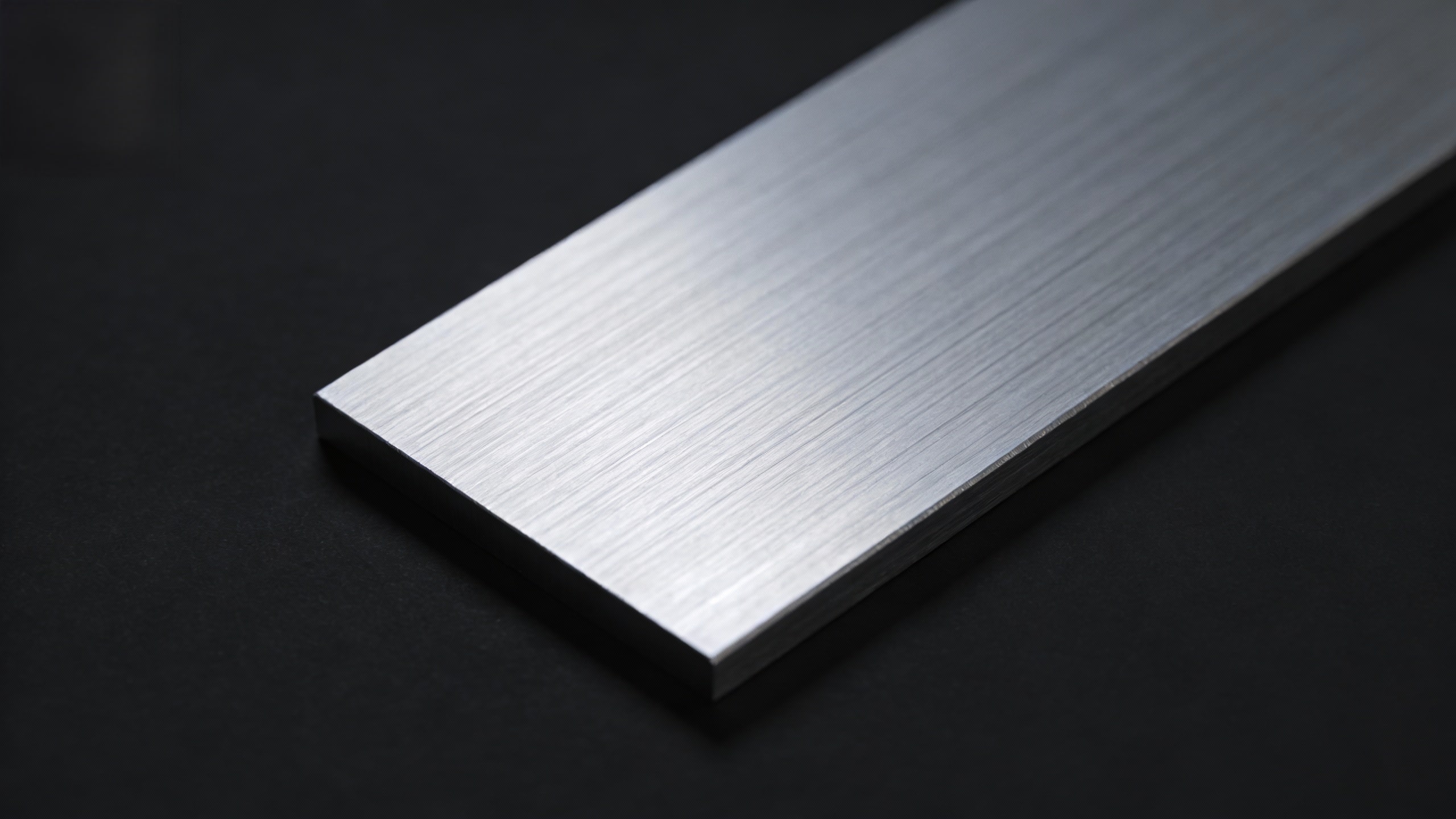

SLM (Selective Laser Melting)

Aluminum Features

1High precision with a granular surface texture and fast molding speed. Strength surpasses that of cast parts. Heat deflection temperature: 600°C, dimensional accuracy: +0.2 mm, tolerance: 0.2% (two-thousandths). 2Enables flexible, efficient design, improves product quality and production efficiency, reduces costs, and creates greater overall value. 3Widely used in medical devices, automotive components, aerospace, home appliances, and related fields. Suitable for structurally complex products and can undergo secondary machining (e.g., turning, milling, polishing).

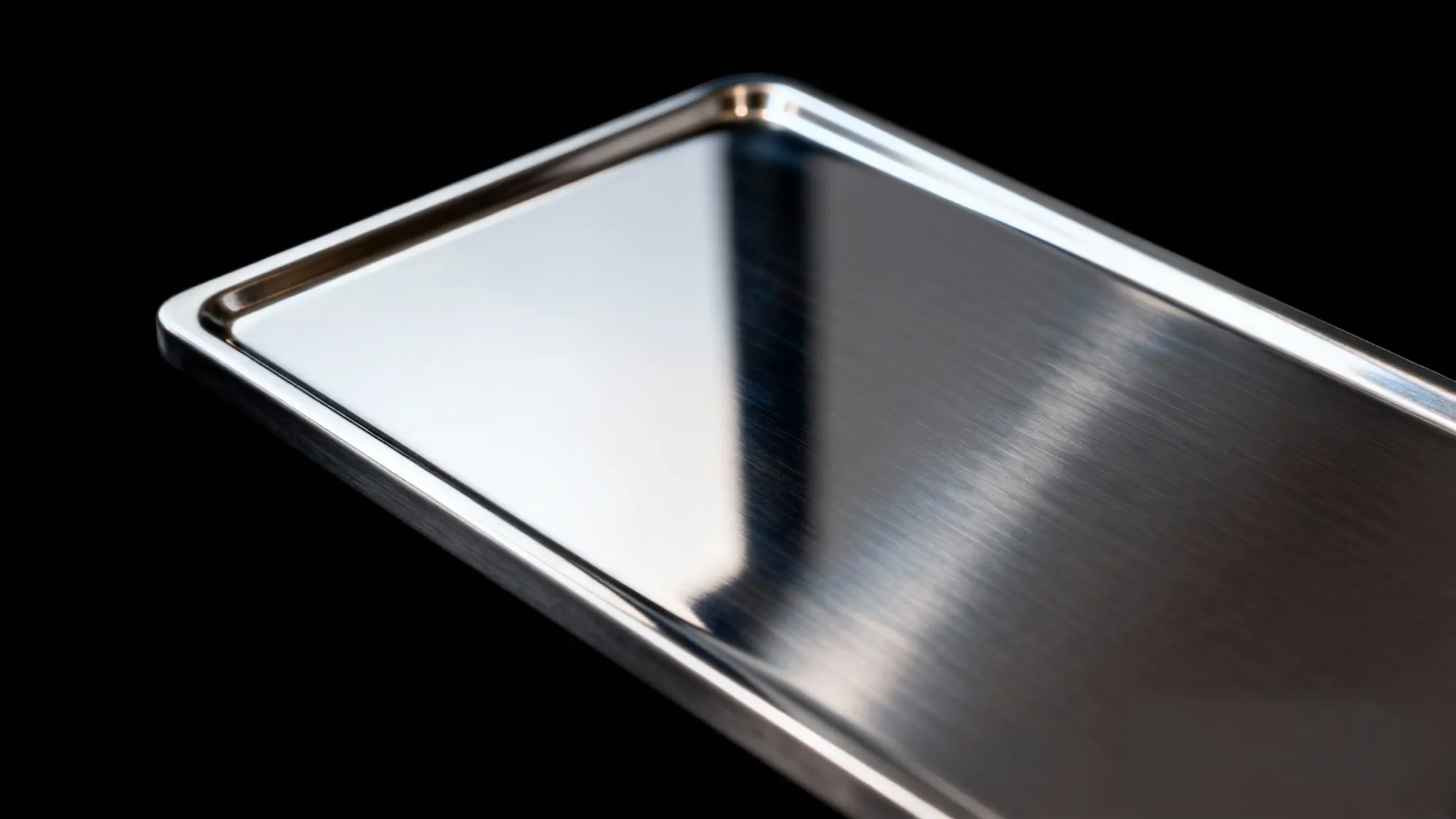

Steel Features

1High hardness with a granular surface texture. 2Can be processed with secondary machining (e.g., turning, milling, polishing). Heat deflection temperature: 1200°C; accuracy: +0.2 mm; tolerance: 0.2% (two-thousandths). 3Ideal for structurally complex products./p>

DLP (Digital Light Processing)

Imported Red Wax

1Exceptionally fine surface details with minimal visible texture. 2Heat deflection temperature: 60°C; accuracy: +0.05 mm; tolerance: 0.05% (half a thousandth). 3Ideal for figurines, jewelry casting, and other applications requiring high precision and fine surface finishes.

Processes Compare

New to our 3D printing service and unsure which additive technology fits your 3D design?

Compare each process's capabilities below to find your application's perfect match.

| Metric | Metric Max Part Size | Metric Min Feature Size | Metric Tolerances | US Max Part Size | US Min Feature Size | US Tolerances |

|---|---|---|---|---|---|---|

| SLM (Selective Laser Melting) | Standard: 300mm x 300mm x 300mm Large Format: 800mm x 400mm x 500mm |

0.4 mm | ±0.1 mm | Standard: 11.8 in. x 11.8 in. x 11.8 in. Large Format: 31.5 in. x 15.7 in. x 19.7 in. |

0.015 in. | ±0.004 in. |

| Stereolithography | 736mm x 635mm x 533mm | 0.0634mm | ±0.0508mm | 29 in. x 25 in. x 21 in. | 0.0025 in. | ±0.002 in. |

| Selective Laser Sintering | 482mm x 482mm x 431mm | 0.762mm | ± 0.254mm | 19 in. x 19 in. x 17 in. | 0.030 in. | ±0.010 in. |

| DLP (Digital Light Processing) | 192mm x 120mm x 200mm | 0.035mm | ±0.05mm | 7.6 in. x 4.7 in. x 7.9 in. | 0.0014 in. | ±0.002 in. |

3D Printing Services

Our Rapid Prototyping service provides high-quality prototypes quickly and accurately by leveraging advanced technologies such as 3D printing, CNC machining, and vacuum casting. This approach accelerates product development and design validation, offering key benefits including speed, cost-effectiveness, precision, and flexibility.

Metal 3D Printing

Fiber laser system to selectively fuse fine metal powder particles, layer by layer, building fully dense metal parts with complex geometries.

Selective Laser Sintering

Ideal for creating durable prototypes and functional end-use parts without the need for support structures.

Multi Jet Fusion

Multi Jet Fusion (MJF) is an industrial-grade additive manufacturing technology that utilizes a multi-agent printing process and an infrared energy source to build functional parts layer by layer, enabling the production of high-quality, durable components.

PolyJet

Produces smooth, accurate parts, prototypes and tooling. With 16-micron layer resolution and accuracy as high as 0.1 mm.

Advanced Photopolymers

When your project demands advanced mechanical properties that surpass the capabilities of (SLA) and PolyJet processes, our portfolio of high-performance photopolymer materials—enabled by Axtra3D's Hybrid PhotoSynthesis (HPS) technology—delivers exceptional strength, thermal stability, and durability.

Stereolithography

Stereolithography is a high-precision 3D printing technology that uses a UV laser to cure liquid resin layer by layer. It delivers exceptional surface finish, fine detail resolution, and tight tolerances, making it ideal for functional prototypes, appearance models, and low-volume end-use parts.

Surface Finish Options

| Type | Option |

|---|---|

| Unfinished | Dots, or standing "nibs," remain evident on the bottom of the part from the support structure remnants. |

| Natural | Supported surfaces are sanded down to eliminate the support nibs. |

| Standard | Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present. |

| Custom | Soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphic, and texture finishes are available. |

Custom Finishing

| Type | Option |

|---|---|

| Clear Coat | Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials. |

| Painting | After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting. |

| Plating | Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium. |

| Dyeing | Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting. |

| Decaling | Decaling can be used to add a logo or other graphics to boost cosmetics or function. |

| Polishing | We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations. |

| Heat Treatment | Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging. |

| Machining | Machine metal 3D prints to achieve exceptional surface finish quality or meet tight tolerances. |

3D Printing Made By Dakings