Precision Turning — Accurate & Efficient

Dakings provides high-precision CNC turning services for cylindrical parts, from miniature components to large shafts, with tight tolerances (±0.002mm) and consistent quality across various industries.

Løsninger

Assurance

Optimization

Evner

Manufacturing

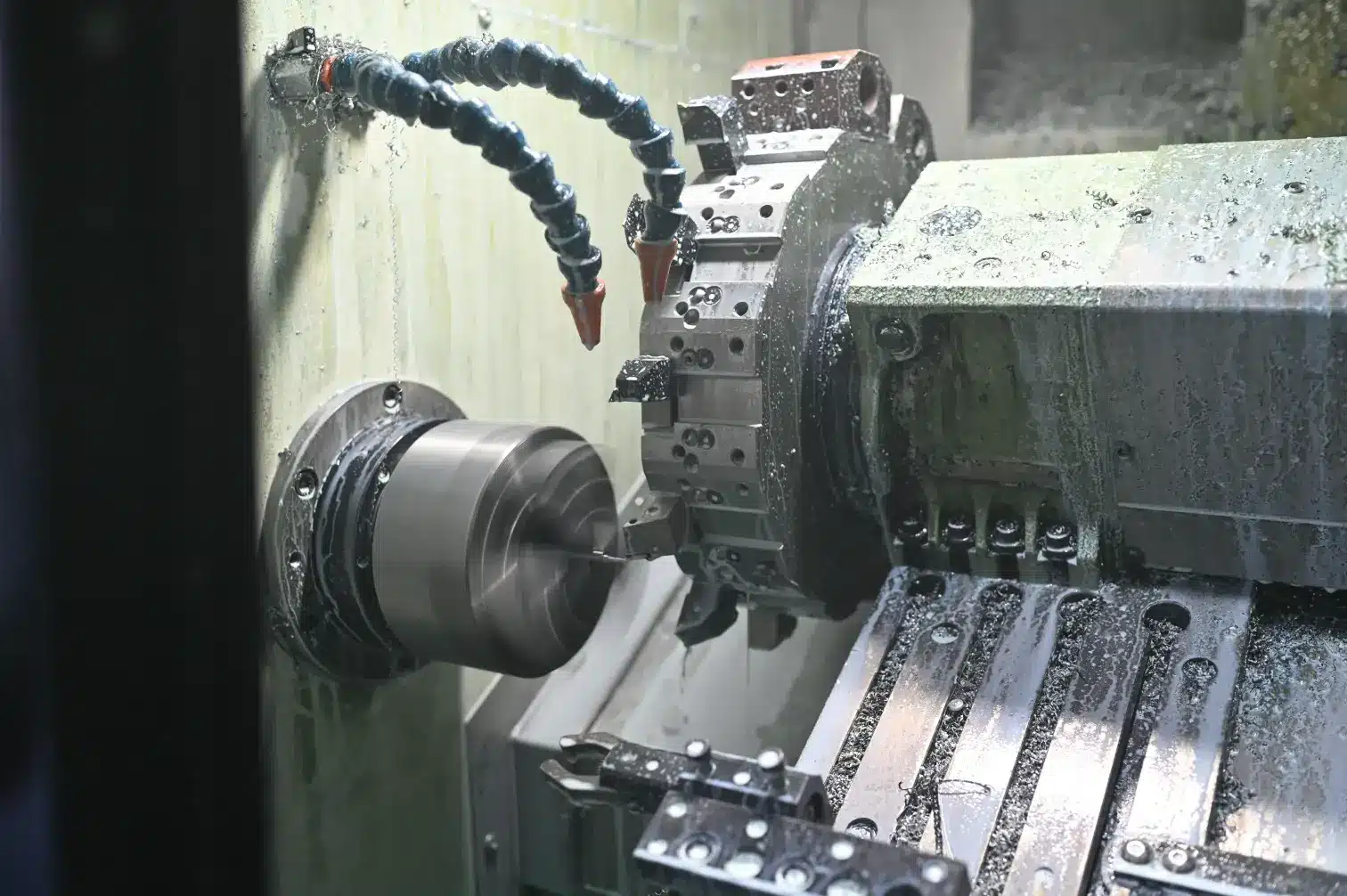

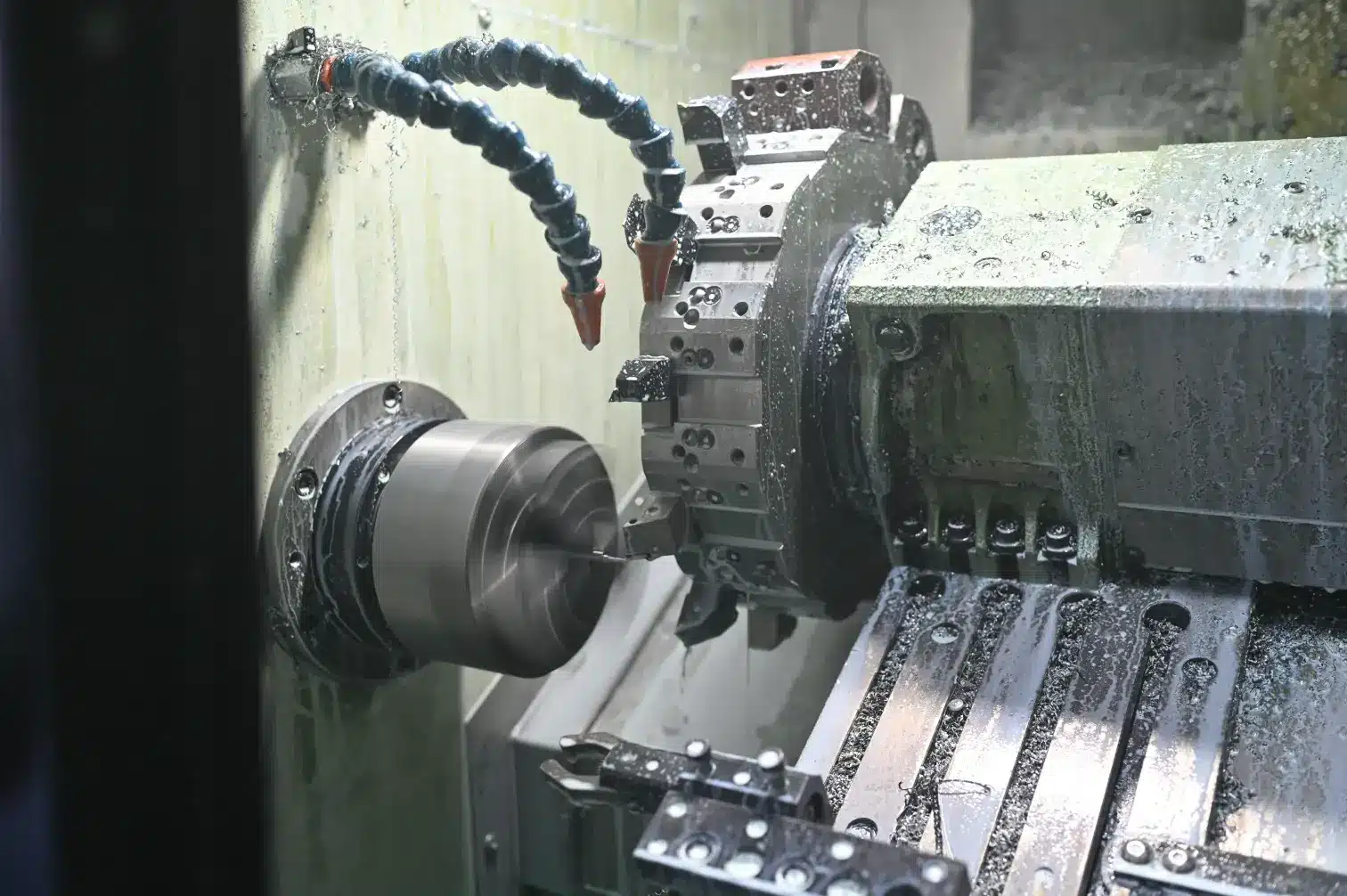

Turning Machining Service

Our CNC turning expertise combines precision, versatility, and efficiency to meet the most demanding part requirements.

External Turning

Precision machining of cylindrical outer diameters to achieve tight tolerances, smooth finishes, and consistent part geometry for shafts and rotational components.

Internal Turning (Boring)

Accurate machining of internal diameters and stepped bores, ensuring excellent concentricity, dimensional accuracy, and reliable functional fit.

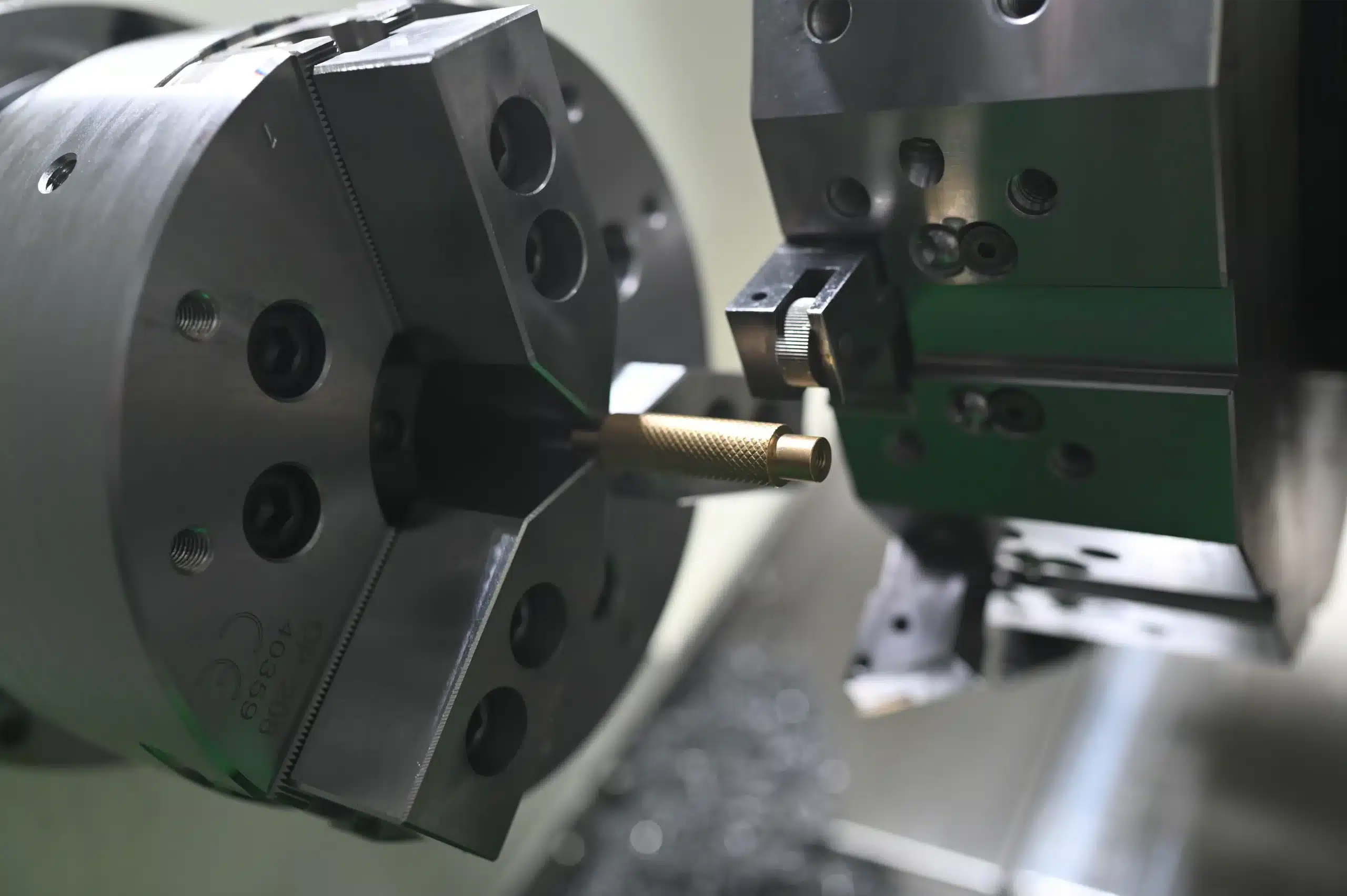

Knurling

Creation of uniform knurled patterns on cylindrical surfaces to enhance grip, assembly handling, and aesthetic appearance.

Drilling

High-precision hole machining with controlled depth and diameter, suitable for mounting, fastening, and functional features.

Precision Machining Tolerance

| Tolerance Lever | Overall Dimension Range | ||||||

|---|---|---|---|---|---|---|---|

| Specifications | ≤3, >0.5 | ≤6, >3 | ≤30, >6 | ≤120, >30 | ≤400, >120 | ≤1000, >400 | ≤2000, >1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Material Library

Composites

Rubber & Elastomers

CNC Turning Surface Finishes

DakingsRapid offers a wide range of surface finishes to help enhance the quality of your products. Surface treatments for CNC turned parts improve aesthetics, surface hardness, wear resistance, and chemical corrosion resistance. Additionally, they can enhance visibility in functional or power transmission applications. Below is a selection of our surface finishing processes.

As Machined

,清晰展示其.jpg)

The surface directly after CNC machining shows the raw machining marks. It is a cost-effective choice but retains tool marks.

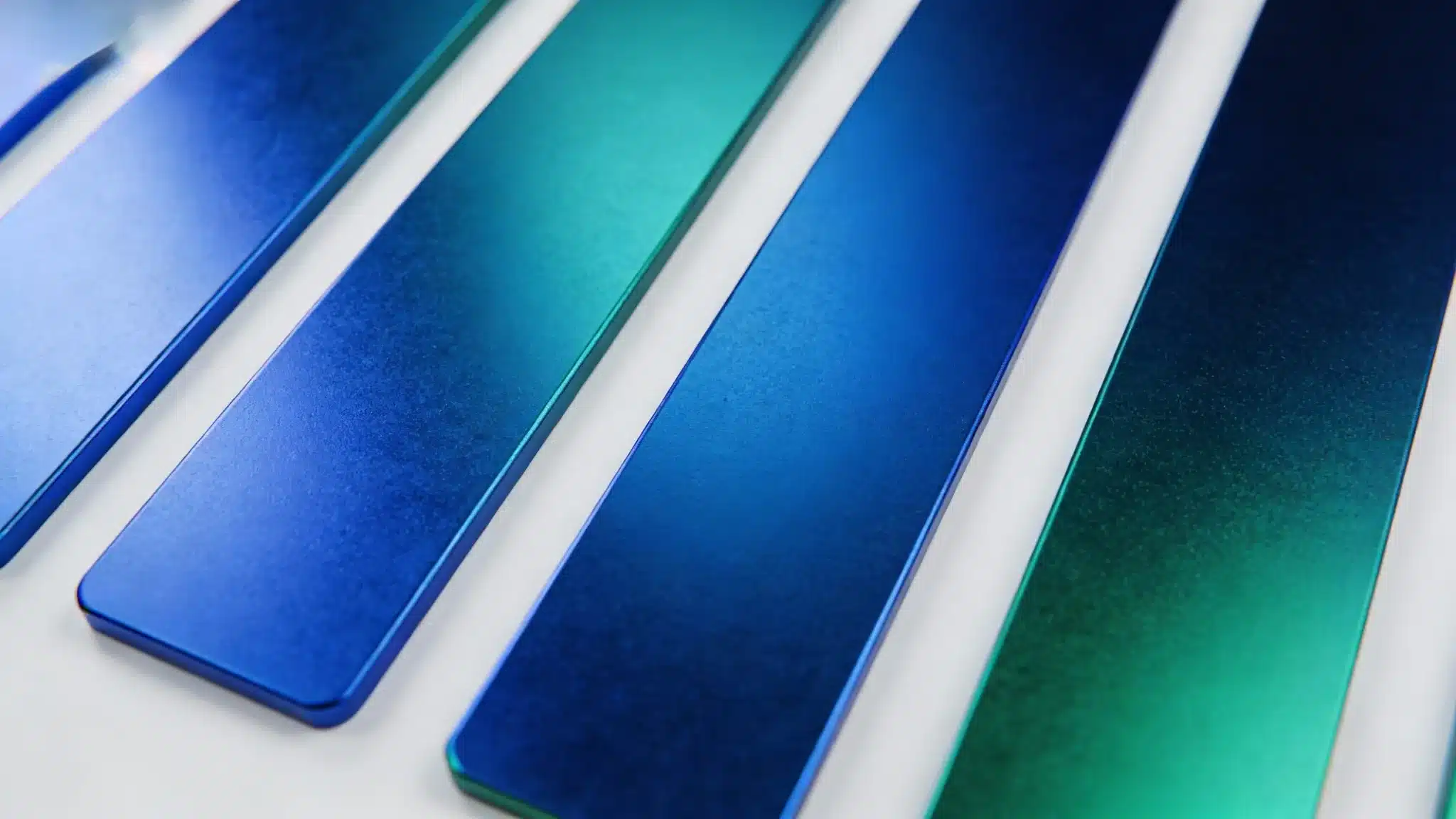

Anodizing

Anodizing improves wear and corrosion resistance. It also allows for coloring, making it an ideal choice for aluminum parts.

Polishing

.jpg)

Polishing achieves a high-gloss surface and reduces surface roughness, enhancing the aesthetic appeal of the metal.

Bead Blasting

Bead blasting uses sand or other media to clean the surface and remove burrs, resulting in a uniform matte finish.

Tumbling

去毛刺处理后的长方形小型金属零件。所有.jpg)

Tumbling uses friction and abrasion inside a drum to smooth small parts and remove burrs, achieving a uniform and textured surface.

Electropolishing

Electropolishing is a chemical process that smooths and brightens the surface while improving corrosion resistance.

Brushed Finish

Brushing creates a unidirectional texture on the surface, reducing the visibility of surface imperfections and scratches.

Powder Coating

Powder coating forms a wear-resistant and weather-resistant layer, available in a wide range of colors and textures for various surfaces.

Electroplating

Electroplating forms a thin metal layer on the part, improving wear resistance, corrosion resistance, and aesthetics.

Black Oxide

表面处理的长方形钢制或铸铁零件。表面呈现深.jpg)

Black oxide is a conversion coating for ferrous metals that improves wear resistance and provides a black or dark grey appearance.

Alodine

处理的长方形铝合金板。表面呈现.jpg)

Alodine coating provides corrosion protection and improves paint adhesion, primarily used for aluminum alloys.

Heat Treatment

。.jpg)

Heat treatment alters the mechanical properties of the metal, thereby increasing hardness, strength, or ductility.

Tolerances for

CNC Turning

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lathes can reach tolerances of up to ±0.005″. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.

| Specification | Detail |

|---|---|

| Maximum Part Size | Typically up to 500 mm in diameter and 1500 mm in length, though larger sizes can be accommodated with specific equipment. |

| Minimum Part Size | As small as 1 mm in diameter, depending on the material and machining setup. |

| General Tolerances | Standard tolerances of ±0.01-0.05 mm; tighter tolerances down to ±0.005 mm can be achieved based on the material and complexity of the part. |

| Lead Time | Standard lead times range from 4-7 days for small batches. Expedited services are available, reducing lead time to 24-48 hours. |

Hvordan kan vi samarbeide?

Fra innsending av design til levering av deler har vi strømlinjeformet prosessen i tre effektive trinn.

Consult Expert Team

Directly communicate with our business specialists. We provide 24/7 online support to discuss your needs immediately.

Get Instant Quote

Our intelligent system provides accurate and competitive pricing in real-time.

Fast Parts Delivery

After rigorous quality inspection, your custom parts are packed securely and shipped via express global logistics.

No hidden fees. Fast response guaranteed.