Surface Finishing: Protect, Enhance, Perfect

Custom surface treatments for corrosion resistance, durability, and design—tailored to Robotics, medical, automotive, and more.

treatments

Quality Assurance

testing

optimization

processing

capabilities

Our Surface Finishing Løsninger

Protect, Beautify, and Engineer Surfaces for Your Industry

Anodizing

Specs:Aluminum | 10–50µm thickness | Salt spray resistance ≥500 hours.

Role:Corrosion protection for aerospace components, medical devices.

Powder Coating

Specs:50–100µm thickness | 100+ colors | UV-resistant.

Role:Durable protection for automotive frames, industrial enclosures.

Electroplating

Specs:2–20µm thickness | Corrosion resistance + electrical conductivity.

Role:Enhances hardware, electrical connectors, and tooling.

Finishing & Branding

Specs:Polishing: Ra ≤0.8µm (mirror/satin finish).

Services:Silk Screening with UV-resistant ink & Black Oxide to reduce friction.

Surface Finishes

,清晰展示其.jpg)

去毛刺处理后的长方形小型金属零件。所有.jpg)

。.jpg)

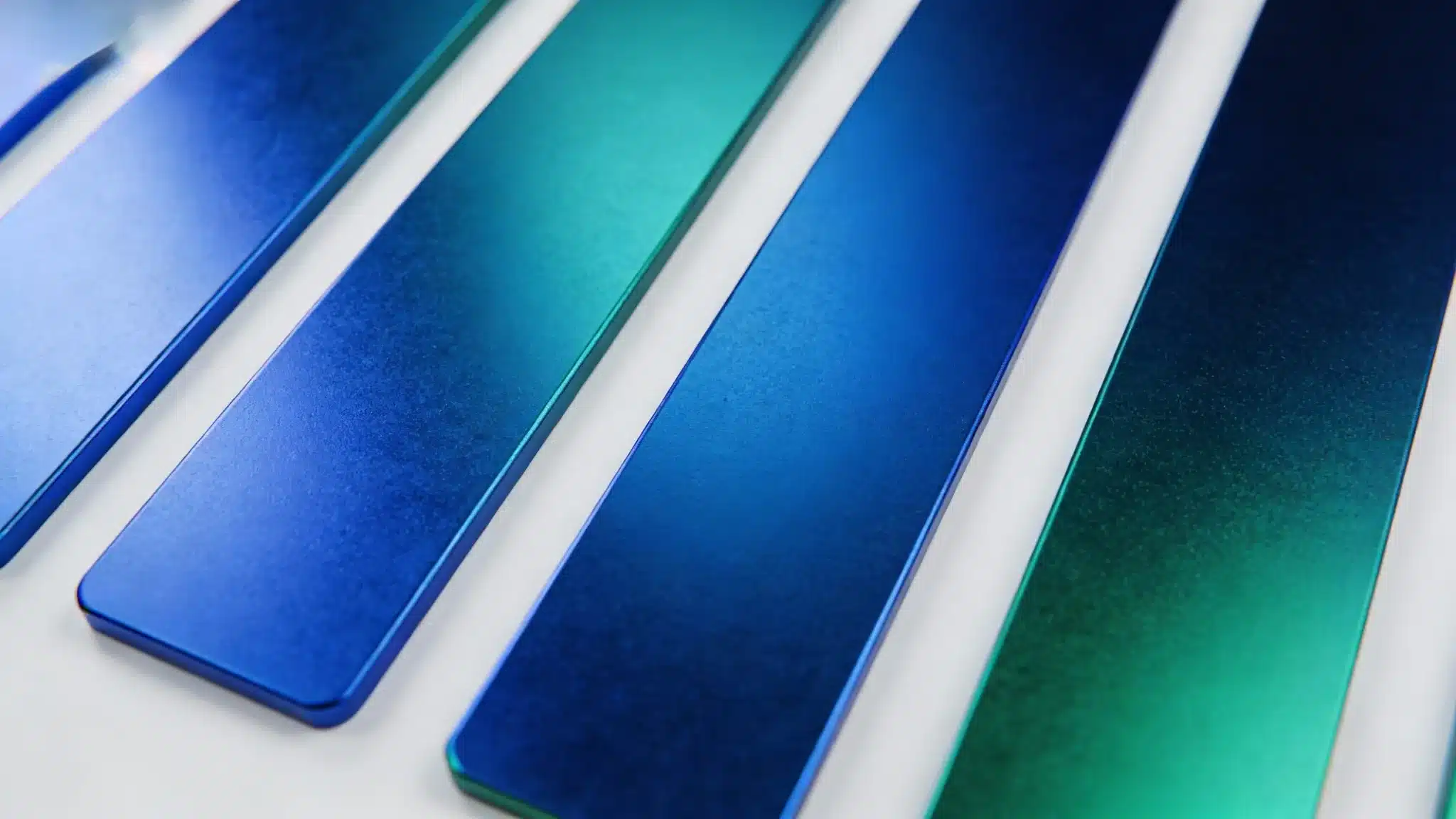

处理的长方形铝合金板。表面呈现.jpg)

涂层处理的长方形铝板。表面覆盖一.jpg)

表面处理的长方形钢制或铸铁零件。表面呈现深.jpg)

标准处理、用于比对的长方.jpg)

Technical Specifications

Key Performance Metrics

| Industry | Finish Type | Thickness | Corrosion Resistance | Application Example |

|---|---|---|---|---|

| Robotics | Anodizing Powder Coating | ≥500 hours (salt spray) 60-80μm | ≥1,000 hours (salt spray) ≥1,500 hours | 20-50μm Robot joints Exterior shells (UV-resistant) |

| Medical Device | Anodizing Electropolishing | 10-25μm N/A (surface) | ≥800 hours (salt spray) ≥1,000 hours | Surgical instruments Implants (hygienic smoothness) |

| Automation | Powder Coating Black Oxide | 70-100μm 0.5-1.5μm | ≥1,200 hours ≥300 hours | Actuator enclosures Gear components (friction reduction) |

| Automotive | Anodizing Powder Coating | 15-30μm 50-100μm | ≥700 hours (salt spray) ≥1,000 hours | Aluminum wheels Chassis parts (impact resistance) |

| Optical Comms | Polishing DLC Coating | Ra ≤0.2μm 2-5μm | N/A (non-corrosive) ≥500 hours | Lens mounts (mirror finish) Fiber optic connectors |

| Semiconductor | Electroplating Parylene Coating | 2-10μm 1-5μm | ≥300 hours (salt spray) ≥1,000 hours | PCB connectors Microchips (hermetic sealing) |

Perfect Your Project's Finish

Elevate your designs with precision finishing. We offer a comprehensive range of surface finishing solutions to improve both performance and visual impact. Whether your priority is durability, functionality, or refined aesthetics, each finishing process is carefully matched to material type, color requirements, texture expectations, and budget considerations. Choose the right finish to enhance product quality, extend lifespan, and deliver a market-ready result.

Start Your Project