Rapid Prototyping and On-Demand Production for

Robotics

Industry

Promote the development of innovative products and the launch of new products in the robotics industry

(5-Axis CNC)

Why Companies Choose DakingsRapid for Robotic Parts

Professional team

Our professional team consists of experienced CNC and robotic machining engineers with deep expertise in precision, structural strength, and assembly consistency, ensuring reliable and efficient delivery of complex components.

Fast Lead Time

Get quotes within minutes and parts within days! With high manufacturing skills and technical experience, our expert robotics engineers will work to reduce cycle time by up to 50%.

High Quality Parts

With 5-axis CNC machining, precision die casting, and wire EDM, Dakingsrapid delivers complex custom robotics parts with high precision tolerances (+/- 0.0001-0.0003") - 10x tighter than the competition.

DakingsRapid's professional robotics team

Led by Technical Director Engineer Huang, the DakingsRapid robotics team has 7 years of experience in the robotics industry and is capable of solving 96% of processing challenges within their specialized field.

Technical Director - Mr.Huang

Humanoid Robot Machining: Head to Legs

The first humanoid to be powered by Carbon, a pioneering Al control system.From 2021 to now, we have cooperated with our customer on this robotics project from head, shoulderships, arms,fingers, legs, etc. Multiple prototypes of the entire project, assembly, testing to release

Experience validation by the DakingsRapid robotics team

Dakings has been deeply involved in the robotics industry for a long time and has a deep understanding and insight into the pain points and challenges of the industry.

![图片8 1 E1767858864744 [薄壁零件加工]](https://www.dakingsrapid.com/wp-content/uploads/2026/01/图片8-1-e1767858864744.jpg)

When dealing with thin-walled parts, machining can easily lead to distortion.

At Dakings, we optimise the machining process and employ stress relief technology to ensure precise control of distortion to deliver high quality results.

![图片9 [機器人零件加工]](https://www.dakingsrapid.com/wp-content/uploads/2026/01/图片9.jpg)

Robot parts require precise dimensional accuracy, especially in areas such as the connection, where concentricity and coaxiality are critical.

At Dakings, we optimise the process and carefully design the machining steps to ensure that critical dimensions are achieved to meet the required tolerances.

DakingsRapid Fast-Track Manufacturing for Robot Parts

We provide support for your urgent projects at any time, helping you quickly launch your new products.

Customer project validation: 18 parts delivered in 10 days, 50 sets of parts delivered in 30 days.

From Process Upgrade to 30% Capacity Growth

In 2025, we upgraded the processing technology for robot components and established a specialized production line for manufacturing these components.

The number of five-axis machining equipment for robot components has increased to 256+.

The dedicated production lines for robot components have been increased to 6+, with a monthly production capacity of over 600 sets.

The robot component inspection team has expanded to over 20 people, ensuring the quality of every single part.

Robotics & automation manufacturing capabilities

CNC Machining

For cost-efficient prototypes and production runs.

- 3-, 4- & 5-axis milling

- Lead times from 5 business days

- Precision tolerance ±0.02mm

CNC Turning

Lathes and live tooling ideal for cylindrical parts.

- 60+ metals & plastics materials

- Lead times from 5 business days

- Complex geometries supported

3D Printing

FDM, SLA, SLS, MJF for rapid prototyping.

- 25+ plastics & 35+ colors

- ±0.5% dimensional accuracy

- Lead times from 1 business day

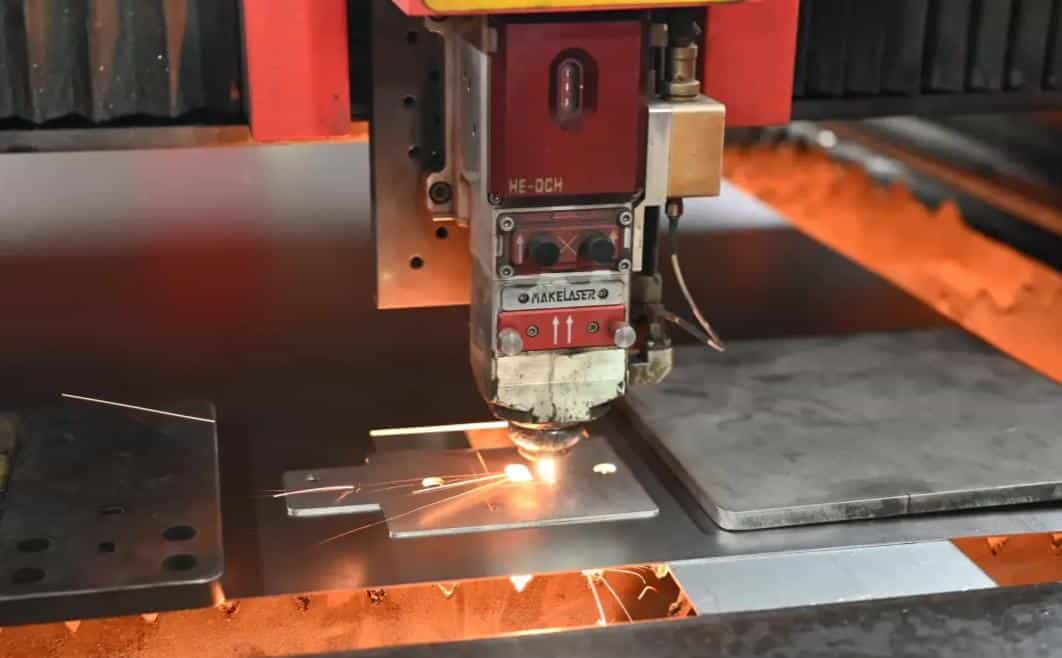

Sheet Metal

Laser cutting, bending, and post-processing services.

- 6 metals & 9 surface finishes

- Tolerances down to ±.004 in

- Lead times from 5 business days

Materials & surface finishes for robotics parts

We provide access to a huge range of high-performance materials and surface finishes that are resilient, reliable, and ready to work.

Robotics materials

Choose from more than 30 metal alloys and hundreds of high-performance plastics.

Robotics surface finishes

Improve precision, wear-resistance, and more with a selection of finishes.

Dakingsrapid Customer Results

Powering the future of robotics. From humanoid agile joints to industrial automation, we deliver high-precision manufacturing solutions.

- Prototyping critical structural parts for Tesla Bot (Optimus)

- Precision machining of lightweight actuator housings

- Heat-treated alloy components for dynamic balance

- Rapid iteration of humanoid robot joint assemblies

- Mass production of high-torque motor housings

- Lightweight limb components for quadruped agility

- Precision gear manufacturing for joint modules

- Surface treatment for wear resistance in dynamic motion

- End-to-end fabrication for humanoid skeletons

- CNC machining of complex multi-axis joints

- Rapid validation of dexterous hand components

- Tolerance control within ±0.01mm for sensor integration

- Ruggedized shells for autonomous mobile robots (AMRs)

- Heat sinks and thermal solutions for AI compute units

- IP67-rated enclosures for outdoor inspection robots

- Low-volume production for specialized robotic tools

- High-precision micro-gearboxes for robotic actuators

- Drive system components for automated logistics

- Compact servo motor housing fabrication

- Durability testing parts for continuous operation cycles

- High-strength aerospace aluminum for bipedal dynamics

- Complex curvature machining for aesthetic robot shells

- Transmission components for high-speed locomotion

- Rapid aluminum casting for chassis structural verification

Expert robotic CNC engineering team

DakingsRapid has a dedicated CNC engineering team with extensive experience in robotics and automation. We understand the requirements for strength, precision, and assembly consistency.

Fast response, shorter development cycle

For rapidly iterating robotics projects, DakingsRapid provides efficient prototyping and stable lead times to accelerate product validation and time to market.

Stable capacity from prototype to mass production

With well-equipped CNC machines and a mature production system, DakingsRapid supports robotic parts from prototyping to reliable mass production.

Strict quality control for robotic applications

DakingsRapid applies strict quality control throughout machining and inspection to ensure dimensional accuracy, tolerance consistency, and long-term reliability.

Case Study