Dakingsrapid Manufacturing Solutions

Dakingsrapid delivers end-to-end supply chain support for complex multi-part BOMs, covering diverse manufacturing processes, custom parts, assemblies, welding, and off-the-shelf component integration. By combining engineering expertise, quality control, supplier coordination, and logistics, we streamline the entire product manufacturing workflow.

-

No minimum order quantities

-

In-region Fictiv teams to oversee production supply chain

-

Advanced inspection, including first article inspection & PPAP

-

End-to-end supply chain management

-

Logistics & tariff optimization services

Production Manufacturing

- Precision CNC machining of complex parts with tight tolerances and scalable tooling

- Mechanical assembly of multi-part products with fastening, bonding, and in-line inspection

- High-volume injection molding with overmolding, multi-shot, and part serialization options

- Tools, dies, and mold design for precision, efficiency, and repeatability at scale

- Anodizing, plating, and surface finishing for functional and cosmetic quality

- CMF manufacturing with precise color matching, material selection, and surface finishes

Production Manufacturing Capabilities & Services

DakingsRapid offers global supply chain services managed by a qualified team of in-region experts—to achieve growth and scalability without the need to add an internal supply chain team.

-

Dedicated engineering support for DFM/DFX

-

Materials and finishing selection assistance

-

BOM consolidation and cost optimization

-

Dedicated Program Manager for seamless supply chain management

Tariff and Logistics

Management

Risk Mitigation

Coordinated and proactive programs to effectively reduce operational costs.

Cost Strategy

Tariff mitigation strategies designed to achieve the lowest landed cost.

Logistics Expertise

In-region expertise optimizing both costs and delivery timelines.

Global Clearance

Customs clearance solutions across land, sea, and air logistics.

Quality & Compliance

-

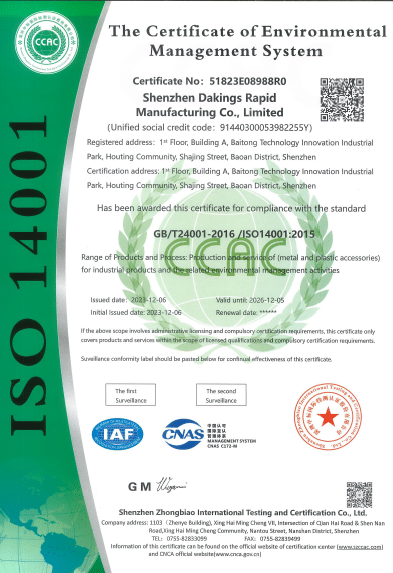

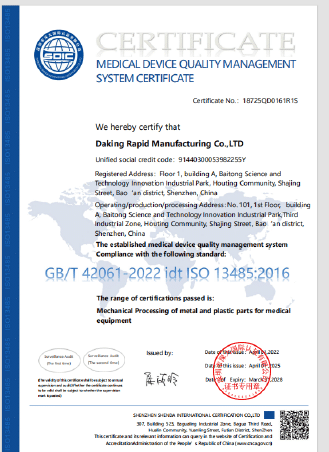

ISO 9001:2015 QMS. Manufacturing centers with , ISO 13485:2016, IATF 16949:2016

-

On-site quality inspections & production audits

-

APQP & PPAP, FAIR

-

Advanced inspection and testing (CMM)

-

Robust QC and QA

How it Works

Streamlined manufacturing from quote to delivery.

Quote a Program

For multi-part BOMs, assemblies, or off-the-shelf components. Your Applications Engineer will reach out within 24 hours.

Proposal Review

Expert proposal creation within 2 business days. Includes line cards, certifications, sourcing strategy, and cost modeling.

Guided Expertise

Portfolio costing analysis, control plans, DFM/DFX, and risk management strategies to consolidate your BOM.

Planning for Production

NPI Readiness Assessment, PLM/ERP planning, Gantt Chart analysis, and comprehensive mold/tool design preparation.

Manufacturing

Full assembly, off-the-shelf components, finishing, and custom parts. Tariff mitigation strategies included.