Why choose DakingsRapid

Transform your idea into a market-ready product—faster, smarter, effortlessly.

Each of our teams possesses over 7 years of in-depth research experience and is capable of solving 97% of the processing challenges in their respective fields.

Trusted by Industry Leaders Nationwide

Dakings Rapid by the Numbers

Trustworthy

48*******9A

DakingSrapid consistently provides high-precision aluminum components to extremely high quality standards. Their delivery speed is impressive.

Samuel Leuman

23*******7B

The parts are perfect! They followed the drawings and 3D data exactly, without the slightest deviation. A very professional team.

Charles Whitlock

56*******2M

Lavorazione di buona qualità. La finitura superficiale delle parti in acciaio inossidabile era eccellente. La spedizione ha richiesto 2 giorni in più del previsto, ma le parti valevano l'attesa.

Marco Rossi

15*******2X

The printouts were incredibly accurate, perfectly matching my design, and worked flawlessly! Their online quote tool was also very intuitive.

Alex Thompson

89*******1L

As partes funcionais funcionam bem, mas o acabamento estético não ficou exatamente como eu imaginava. Havia algumas marcas visíveis de ferramentas que exigiram polimento manual.

Lucas Mendes

99*******1Q

The parts we ordered arrived ahead of schedule, and the dimensional tolerances were all within the promised range. Secure packaging too.

Todd Harrison

34*******9S

Excelente comunicación por parte del equipo de ingeniería. Uno de los orificios estaba ligeramente apretado, pero aún dentro de los límites de tolerancia. En general, una experiencia muy buena.

Sofia Garcia

33*******8L

An exceptional experience! The tiny nylon parts printed by SLS 3D are critical to our production applications, and the quality is impeccable.

Michael Turner

91*******5R

Very cost-effective solution for our low-volume production run. The anodizing color was slightly different from the sample, but acceptable.

Ravi Patel

77*******5K

Der Kundenservice hat sehr schnell reagiert und alle unsere Fragen während des CNC-Bearbeitungsprozesses geklärt. Sehr empfehlenswert!

Sarah Jung

82*******0J

精密加工の公差は極めて厳密に管理されており、業界基準を完全に満たしています。表面仕上げも非常に滑らかです。

Kenji Sato

44*******3F

Du téléchargement des fichiers CAO à la réception des pièces, tout le processus s'est déroulé sans encombre. La qualité du moulage par injection a dépassé nos attentes.

Pierre Laurent

21*******4D

Fast turnaround time and excellent communication. The team helped optimize our design for manufacturing, saving us costs.

David Henderson

65*******2P

The surface finish on the anodized aluminum parts was flawless. Truly professional quality that represents our brand well.

Jessica Miller

98*******7T

We have used several suppliers, but this is by far the most consistent. Dimensions are always spot on.

Thomas Reynolds

42*******8K

Received the order from Dakingsrapid quickly. The parts function correctly, but there were minor cosmetic scratches on the surface. Packaging could be improved.

Robert Kingsley

19*******3B

First time using Dakingsrapid. The pricing is very competitive, but email responses were a bit slow due to timezone differences. Parts are okay for the price.

Kevin Brooks

How DakingsRapid Outperforms

Precision, scale, and speed that the competition can't match.

| Them |

INDUSTRY LEADER

DAKINGSRAPID

|

|

|---|---|---|

| Tolerances | CNC milling down to 0.0010", 10-50x looser. |

Ultra-precision down to ±0.0001-0.0003" across all processes.

|

| Geometries | Often unable to machine hard-to-reach features. |

Complex geometries supported for 12+ years.

|

| Finishing | Limited: mechanical, anodizing, powder coat. |

Full Menu: Anodizing, plating, painting, custom coatings & more.

|

| Assembly | Rudimentary: dowel pins, helicoils. |

Comprehensive kitting & BOM builds ready for market.

|

| Quality | Basic reports, no advanced GD&T. |

Robust QMS: CMMs, advanced GD&T, & full traceability.

|

Traditional Suppliers & Digital Marketplaces VS. DakingsRapid

See how Dakings Rapid stacks up on speed, quality, scale, support, and risk.

| Traditional Suppliers | Digital Marketplaces | Dakingsrapid | |

|---|---|---|---|

| Speed | Slow quotes, inconsistent lead times | Instant quotes, little follow-up—delivery not guaranteed | Instant quotes & fast, reliable lead times |

| Quality | Inconsistent checks, manual oversight | Little to no oversight | QMS, in-region inspections, certified materials |

| Scale | Narrow, regional capacity | Broad but unvetted | It owns two large factories in China, each with an area exceeding 15,000 square meters. |

| Support | Minimal service | Digital-only, self-serve | Real engineers, dedicated PMs |

| Risk | Exposed to tariffs & disruptions | Lowest-bidder sourcing | Trusted suppliers with regular audits, tariff risk management, multi-region resilience |

Major Industries

Dakings specialises in 6 main industries as above, servicing your projects with team specializationsby Industry. These teams not only have in-depth industry knowledge, but also keep abreast ofindustry trends to provide customised solutions to our clients.

Robotics

From intelligent collaborative arms to autonomous mobile robots, we provide high-precision, high-reliability core components and system integration solutions.

In-depth understanding →

Medical Device

Committed to the innovative research and development of medical imaging, diagnostic instruments and surgical assistance systems, we safeguard life and health through precision manufacturing.

In-depth understanding →

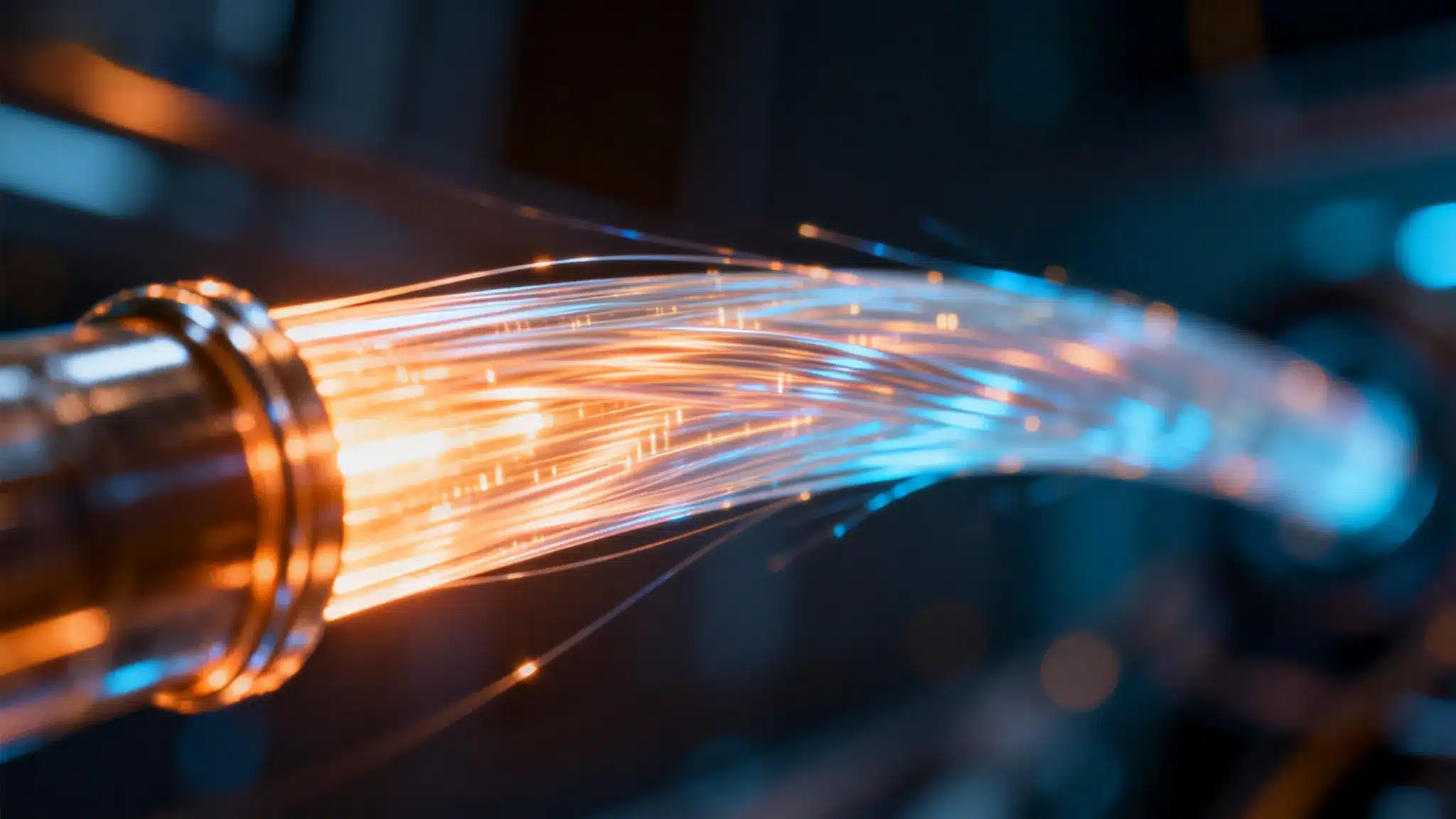

Optical Communictaion

Build the foundation for next-generation high-speed optical networks and provide high-performance solutions from optical modules to core switching equipment.

In-depth understanding →

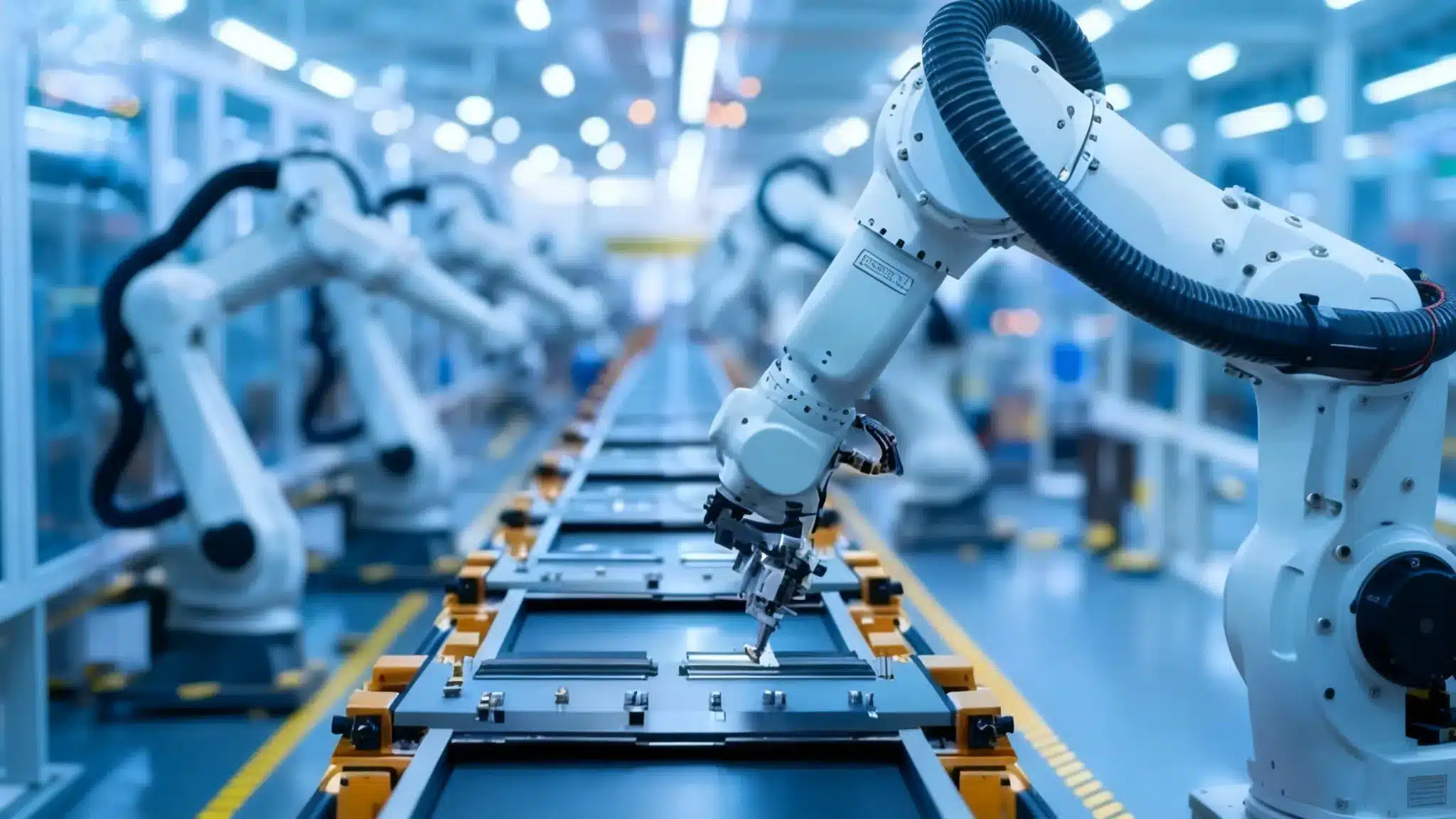

Automation

Customized Automated Parts: Non-standard solutions for the electronics, medical, and new energy sectors that combine precision and cost-effectiveness – fast, reliable, and competitive.

In-depth understanding →

Automotive

Precision automotive components: Every system embodies superior engineering.

In-depth understanding →

Semiconductor

Precision semiconductor component and part manufacturing: Micron/submicron tolerance solutions for semiconductor equipment, wafer fabrication, and packaging testing.

In-depth understanding →Quality You Can Trust

Precision parts with full inspection reports and traceability every time.

-

ISO 9001:2015 QMS → Consistent, repeatable quality

-

ISO 13485:2016, IATF 16949 → Certified partners for medical, automotive, and aerospace

-

Inspection photos & reports → Documentation with every order

-

Advanced GD&T inspection → Accuracy to your tightest specs

Capacity Without Compromise

Global capacity and flexible tooling with high quality at scale.

- 70+ vetted manufacturing partners → Proven partners, not lowest-bid auction winners

- 4 manufacturing regions & GlobalFlex tooling → Shift work for cost, speed, or continuity

- 1 to 1M+ parts → Scale without re-sourcing or switching suppliers

Prototype to Production

Every process from start to scale, all in one platform.

- CNC, 3D, Turning machining, sheet metal, and more → Complete coverage

- Full BOM support → Custom parts & off-the-shelf components, assemblies, hardware, coatings, finishes

- No minimum order quantities → Start small, then scale

Smarter Sourcing, Powered by AI

Digital tools that deliver speed, accuracy, and transparency.

- Instant quoting → Pricing in minutes or hours, not days

- Automated DFM & mold flow simulation → Prevent costly redesigns

- Order & project tracking → Full visibility from quote to delivery

Experience You Can’t Automate

Real engineers and program managers working alongside you.

- Dedicated program managers → One consistent point of contact

- Pre- & post-order design reviews → Proactive guidance at every stage

- Expertise on demand → Decades of practical manufacturing and supply chain experience

DakingsRapid Customer Results

Startups, scale-ups, and Fortune 500 companies rely on DakingsRapid to accelerate innovation, reduce costs, and deliver at scale.

- High-precision machining for orbital station parts

- Advanced Titanium alloy processing & heat treatment

- 100% quality inspection rate for mission-critical loads

- Zero-defect delivery for national strategic projects

- Reduced joint assembly weight by 25% via CNC

- High-strength Al 7075 parts for dynamic movement

- Prototype to volume production in 3 weeks

- Complex multi-axis machined geometries

- ±0.005mm tolerance for surgical arm actuators

- Bio-compatible PEEK & Titanium machining

- ISO 13485 compliant manufacturing process

- Surface finish Ra 0.4 for sterility

- Rugged sheet metal chassis for AGV fleets

- Cost-effective injection molding for sensor housings

- Durability tested for 24/7 operation

- Rapid assembly fixture fabrication

- Carbon fiber reinforced nylon 3D printing

- Aerodynamic optimization via rapid iteration

- Lightweight frame reduced power consumption by 15%

- Impact-resistant landing gear components

- Complex 5-axis machining for wrist joints

- Simulated human skin textures via vacuum casting

- Integration of 50+ sensors in compact housing

- Just-in-time delivery for expo prototypes

- Functional dashboard prototypes in 5 days

- Heat-resistant materials for battery housing tests

- Clear polycarbonate lenses for lighting concepts

- Seamless fit verification for interior trims

- Wind-tunnel ready aerodynamic parts (SLA/SLS)

- High-temp intake manifolds via Nylon 12 GF

- On-demand spare parts for track testing

- Reduced vehicle weight by optimizing brackets