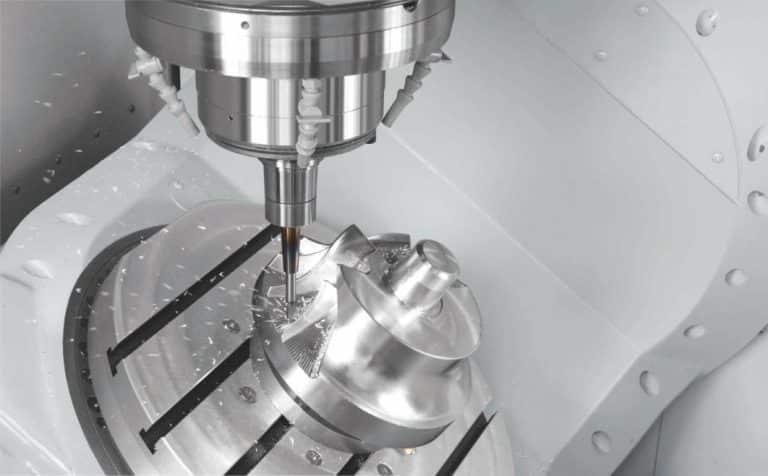

Optimizing Design for Manufacturing (DfM) for stainless steel components requires a strategic approach to mitigate the material’s low thermal conductivity and high ductility, which predispose it to work hardening. Unlike free-machining aluminum, grades such as 304 and 316 demand robust part geometries to resist significant cutting forces; designers should prioritize larger internal corner radii to accommodate rigid tooling and avoid deep, narrow pockets that restrict coolant access. Furthermore, adhering to conservative wall thickness thresholds—typically exceeding 1.5 mm—is critical to prevent chatter and deflection, ensuring that dimensional tolerances are maintained without inducing excessive tool wear or thermal distortion.

Cost Drivers and Optimization Strategies in CNC Machining

The cost structure of CNC machining is defined by the complex interplay of material properties, machine utilization, and labor overhead. Material expenses encompass not only raw stock prices but also machinability ratings; harder alloys increase cycle times and accelerate tool wear, directly inflating hourly operational costs. Labor expenditures are bifurcated into variable run-time monitoring and fixed Non-Recurring Engineering (NRE) tasks—such as CAM programming and fixture setup—which disproportionately impact low-volume production where setup charges cannot be amortized efficiently. Furthermore, geometric complexity and stringent Geometric Dimensioning and Tolerancing (GD&T) requirements necessitate specialized tooling and prolonged inspection cycles, significantly raising the cost per unit. Consequently, achieving economic viability requires the strategic application of Design for Manufacturing (DfM) principles to simplify geometries and relax non-critical tolerances, ensuring that productie resources are allocated strictly to functional requirements.

Strategies for Cost-Effective Product Design and Manufacturing

Optimizing product design for manufacturing cost requires a strategic balance between geometric complexity, material machinability, and assembly logic. By rigorously applying Design for Manufacturing (DfM) principles, engineers can reduce cycle times and tool wear through feature simplification—such as maximizing corner radii and limiting cavity depths—and by consolidating multi-part assemblies into single components to eliminate downstream fastening operations. Critically, material selection must align strictly with functional requirements; avoiding the over-specification of hard-to-machine superalloys in favor of readily available, free-machining grades significantly lowers both raw stock and operational expenditures. Ultimately, standardizing tolerances and dimensions to utilize off-the-shelf tooling further mitigates Non-Recurring Engineering (NRE) costs, ensuring economic viability without compromising performance.

Holistic Approaches to Manufacturing Cost Optimization

Cost reduction in CNC operations demands a systematic approach that bridges shop floor efficiency with upstream engineering decisions. Implementing Lean Manufacturing and Six Sigma protocols allows facilities to isolate bottlenecks and eliminate non-value-added movements, while the integration of predictive maintenance systems uses real-time analytics to prevent unplanned equipment downtime and catastrophic tool failure. Parallel to these operational improvements, strategic supply chain management—leveraging bulk purchasing and diversified vendor networks—stabilizes material expenditures. Ultimately, however, the most substantial savings are realized through Design for Manufacturability (DFM); by simplifying geometries to minimize re-fixturing, relaxing non-critical tolerances, and prioritizing materials with high machinability ratings, manufacturers can significantly reduce cycle times and scrap rates while maintaining component functionality.

Optimizing TCO through Supply Chain Integration

Optimizing total cost of ownership (TCO) in CNC manufacturing requires a holistic supply chain strategy that extends beyond simple raw material price negotiation. By implementing Just-In-Time (JIT) inventory protocols and consolidating logistics, manufacturers can minimize storage overhead and transportation variability. Furthermore, engaging suppliers early in the Design for Manufacturing (DfM) phase leverages their specialized material knowledge to identify cost-effective alternatives and process improvements before production begins. This collaborative approach, supported by predictive analytics for demand forecasting, shifts the focus from initial acquisition costs to long-term operational efficiency, accounting for indirect factors such as tooling longevity, machine downtime, and energy consumption.

Key Performance Indicators for CNC Cost Analysis

Validating cost reduction strategies in CNC manufacturing demands a rigorous audit of both financial and operational metrics, moving beyond basic ROI calculations to granular shop-floor analytics. Process efficiency is best quantified through Cycle Time Analysis and Overall Equipment Effectiveness (OEE) monitoring, which isolate variables such as spindle uptime, tool changeover duration, and operator handling time. Critical Key Performance Indicators (KPIs)—specifically First Pass Yield (FPY), material utilization rates, and throughput—serve as diagnostic tools; for instance, escalating scrap rates often signal the need for preventative maintenance or G-code optimization. By correlating these data points with production costs, manufacturers can shift from reactive troubleshooting to predictive process control, ensuring that capital investments yield measurable improvements in unit profitability.

Cost Reduction Strategies Comparison

| Strategy | Impact on Cost | Implementation Complexity | Time to Results |

|---|---|---|---|

| Design Simplification | Hoog | Medium | Short-term |

| Material Selection Optimization | Hoog | Laag | Immediate |

| Design for Manufacturability (DFM) | Zeer hoog | Hoog | Medium-term |

| Supplier Collaboration | Medium | Medium | Long-term |

| Continuous Improvement | Medium | Hoog | Long-term |

| Supply Chain Management | Hoog | Hoog | Medium-term |

Referenties

- “Design Optimization for a CNC Machine” by Alin Resiga

This study investigates optimal machining parameters, such as cutting speed and feed rate, to enhance cost efficiency.

Read more here - CNC Cost Reduction Checklist

A practical guide with 15 design tips to minimize CNC machining costs, including recommendations on cavity depth and other parameters.

Read more here - “Design and Development of a Target-Costing Model”

This paper develops a target-costing model for machining processes, focusing on cost-effective parameter selection.

Read more here - CNC-bewerkingsdiensten voor roestvrij staal

- “Design Optimization for a CNC Machine” by Alin Resiga