Optimizing Design for Manufacturing (DfM) for stainless steel components requires a strategic approach to mitigate the material’s low thermal conductivity and high ductility, which predispose it to work hardening. Unlike free-machining aluminum, grades such as 304 and 316 demand robust part geometries to resist significant cutting forces; designers should prioritize larger internal corner radii to accommodate rigid tooling and avoid deep, narrow pockets that restrict coolant access. Furthermore, adhering to conservative wall thickness thresholds—typically exceeding 1.5 mm—is critical to prevent chatter and deflection, ensuring that dimensional tolerances are maintained without inducing excessive tool wear or thermal distortion.

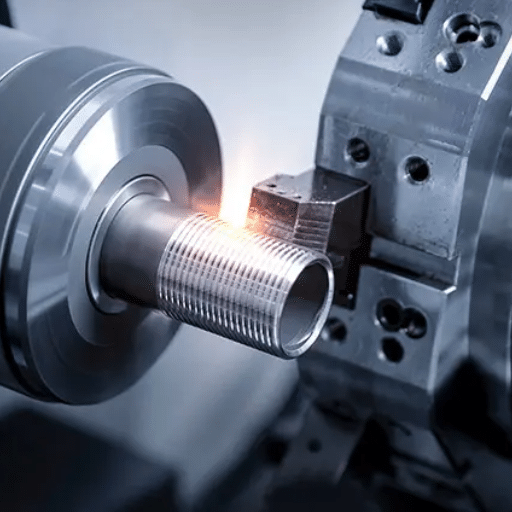

Optimizing Thread Design for Stainless Steel Components

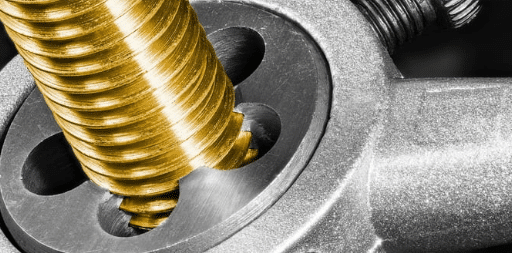

Optimizing thread design for stainless steel components is critical to preventing common failure modes such as galling (adhesive wear) and work-hardening during manufacturing. Because austenitic grades like 304 and 316 exhibit high ductility, they are prone to seizing during assembly; therefore, engineers should prioritize coarse thread pitches and specific tolerance classes (e.g., 2A/2B) that allow sufficient clearance for anti-seize lubrication. Effective design also necessitates the integration of undercut reliefs to reduce stress concentrations and a careful evaluation of the alloy’s composition—balancing the superior corrosion resistance of nickel-chromium grades against the improved machinability of martensitic or ferritic alternatives. Ultimately, producing durable threads in these tough materials requires rigid tooling setups and aggressive coolant application to counteract the metal’s tendency to deform plastically rather than shear cleanly.

Material Selection Guidelines for Threaded Components

Selecting the appropriate material grade for threaded components requires balancing machinability with specific environmental and mechanical performance requirements. While austenitic stainless steels like 304 offer adequate corrosion resistance and easier machining for general assembly, the molybdenum-enriched composition of grade 316 is necessary for threading applications in chloride-rich or marine environments to prevent pitting and stress corrosion cracking. Conversely, carbon steels are categorized by carbon content to match structural loads: low-carbon variants prioritize weldability for general construction, medium-carbon grades are heat-treated for wear-resistant machine elements like gears and axles, and high-carbon tool steels are utilized for cutting edges requiring maximum hardness and abrasion resistance. Ultimately, the threading process itself—whether cutting or rolling—must be aligned with the material’s ductility and work-hardening tendency to ensure fatigue strength and dimensional fidelity.

304 vs 316 Stainless Steel Comparison

When choosing between stainless steel grades, SS 304 and SS 316 are the two primary options, each with unique properties suitable for different applications. Both are essentially austenitic stainless steels. This means they are non-magnetic and offer excellent corrosion resistance, though slight differences in their chemical composition can lead to distinct performance characteristics.

Comparison Table

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium Content | 18-20% | 16-18% |

| Nickel Content | 8-10.5% | 10-14% |

| Molybdenum Content | Geen | 2-3% |

| Corrosiebestendigheid | Goed | High (especially against chlorides) |

| Tensile Strength | 505-600 MPa | 515-620 MPa |

| Kosten | Onder | Hoger |

Understanding the specific advantages and limitations of 304 and 316 stainless steel will help you select the most suitable grade for your application's environment and performance requirements.

Strategic Selection of Threading Tools and Inserts

Selecting optimal threading instrumentation requires a systematic evaluation of workpiece machinability, hole topology, and production volume to ensure dimensional fidelity and process stability. While High-Speed Steel (HSS) remains the industry standard for general ductility, machining abrasive or high-tensile superalloys often demands cobalt-enriched substrates or solid carbide tools treated with friction-reducing coatings like Titanium Carbonitride (TiCN) to mitigate thermal degradation. Chip evacuation strategy is equally critical; engineers must specify spiral-point taps for through-holes to eject swarf axially forward, whereas spiral-flute geometries are required for blind holes to extract chips rearward and prevent packing. Beyond cutting tools, the integration of helical inserts is a standard Design for Manufacturing (DfM) practice for reinforcing threads in low-shear-strength materials such as aluminum or plastics, significantly enhancing fatigue resistance and allowing for repeated assembly cycles without thread degradation.

Voeg hier je koptekst toe

Effective thermal management is paramount in threading operations, where the combination of high friction and rapid plastic deformation predisposes materials—particularly work-hardening alloys—to strain hardening. If heat is not evacuated efficiently from the shear zone, localized temperature spikes can accelerate microstructural changes that drastically increase workpiece hardness, leading to premature tool failure, surface finish degradation, and dimensional non-conformance. To mitigate these risks, engineers must implement aggressive cooling strategies, prioritizing High-Pressure Coolant (HPC) systems with nozzles precisely targeted at the cutting interface to penetrate the vapor barrier and provide necessary lubricity. Furthermore, minimizing tool dwell through optimized feed rates and utilizing sharp, coated cutting geometries are essential practices to prevent the onset of work hardening and ensure consistent thread quality.

Achieving high-precision threading necessitates a holistic control strategy that integrates cutter geometry, machine kinematics, and thermal management. Operators must select application-specific tooling with optimized rake angles to maintain profile fidelity, strictly monitoring cutting edges for wear that could introduce pitch errors or surface irregularities. Beyond tooling, dimensional accuracy relies on rigid workholding and precise spindle calibration to eliminate runout and chatter during the cutting cycle. Furthermore, the synchronization of calculated feeds and speeds with targeted lubrication is critical for dissipating shear heat, thereby preventing thermal distortion and ensuring compliance with strict tolerance classes.

Process reliability in CNC threading hinges on the precise control of cutting parameters, lubrication, and machine alignment. Deviating from optimal surface speeds or feed rates generates excessive shear heat, leading to rapid tool degradation and dimensional variance. This instability is compounded by inadequate coolant application, which increases friction and the risk of galling, particularly in ductile materials. Furthermore, maintaining strict concentricity between the cutter and workpiece is essential; even minor axial misalignment or fixture runout inevitably results in defective thread profiles and scrapped components, underscoring the need for rigid setup verification.

Referenties

- Threads and Design Considerations

This document discusses the length of thread engagement and other design considerations for threaded components.

Read more here - Fastener Handout

Provides insights into thread height and engagement, especially for materials like steel.

Read more here - Production of Small Holes and Threads

Explores methods like cutting, cold forming, and milling for producing internal threads.

Read more here - CNC-bewerkingsdiensten voor roestvrij staal