Quality Control & Assurance Done Right

DakingsRapid delivers stringent quality control and assurance, expert boots on the ground, and a digital platform built to keep your production moving.

We Ensure Quality in

Every Step

STEP 01

Pre-Production

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment of your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

Material verification

On our customer's request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

STEP 02

In-Production

On-site inspection system

In precision machining, materials being worked on must be always in the right position. With an on-site inspection system, positions are examined automatically, and adjustments are made accordingly. Using an on-site inspection system further helps avoid issues at the early stage, saving cost and time.

In-process quality control

At DakingsRapid, we strictly obey the ISO9001:2015 requirements. The quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

STEP 03

Final-Production

Full-dimensional inspection report

For all orders, we provide full dimensional inspection reports on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc.

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

Industry Standards and Certifications per 2D Drawings and PO Requirements:

-

Material Certificates (robust supply network of tested and traceable raw materials)

-

Certificates of Conformity

-

Certificates of Analysis

-

Robust GD&T per ISO 2768 (unless 2D drawing provided)

-

Finishing, testing, inspection, and compliance industry standards met

-

REACH and RoHS

Production-Grade Quality Inspection Capabilities

Dakings Rapid offers a wide range of quality inspection services per industry standards with state-of-the-art equipment.

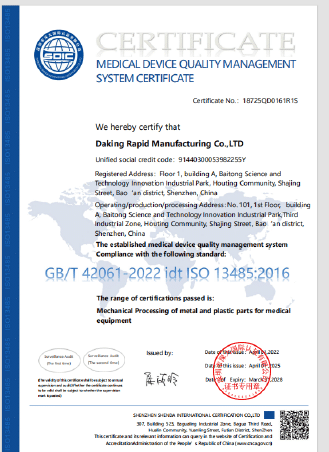

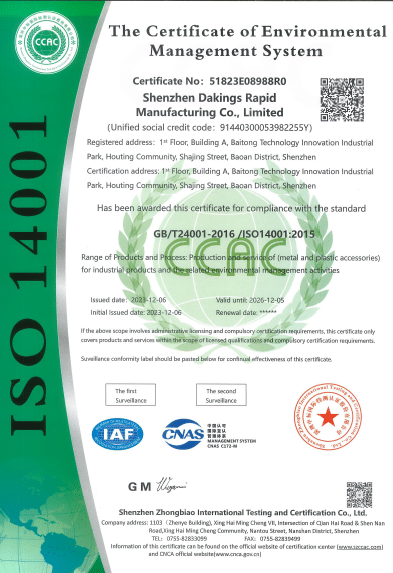

Certifications

Our employees

Dakingsrapid employees trained and assessed to ensure the highest quality inspection.

Quality Control Inspector

Responsible for confirming the parts in an order meet all customer requirements prior to releasing the orders for shipment to the customer. Perform physical part inspection and/or remote inspection.

Supplier Quality Engineer

Our supplier quality team audits and vets manufacturing centers within our network to our internal quality standards. Work directly with suppliers to ensure supplier performance and resolve quality issues promptly.

Supplier Quality Onboarding and Management

Dakingsrapid identifies manufacturing centers that have the equipment, capacity, and expertise necessary to meet project requirements.

- Initial audit with our quality, sourcing, and manufacturing experts

-

Internal review and approval process, including physical testing of quality and manufacturing capabilities. Dakingsrapid quality assessment includes:

- Use of SPC and other statistical controls

- Mitigation of unplanned changes and quality issues

- Control their externally provided processes

- Manufacturing center training to Dakingsrapid Quality Standards, inspection protocols, and CAR/CAPA management

- Continual evaluation of manufacturing center performance and continuous improvement

- Periodic on-site quality audits and weekly ratings

Self-Owned Factories and Manufacturing Network

At DakingsRapid, our factory is equipped with state-of-the-art tools and technologies. Our professional team operates CNC machines and high-performance equipment, including laser cutting machines, bending machines, welding equipment, and modern 3D printers.

By managing our manufacturing in-house, we keep a close eye on quality at every step. This helps us maintain high standards, offer flexible scheduling, and provide affordable solutions without sacrificing quality.

World Class Quality

Precision engineering meets digital perfection. Overseeing development from factory to delivery.

Quality Assurance

Real-time data calibration and automated inspection protocols ensures zero-defect output.

Smart packaging verification and predictive delivery tracking systems.

Quality Control

High-precision mechanical analysis performed by elite technicians.

Blockchain-ready inspection reports and digital twin documentation.

Frequently Asked Questions

How does Dakingsrapid ensure quality with a distributed network of manufacturing partners?

DakingsRapid maintains strict product conformity through a structured supplier qualification and continuous improvement system. Our controlled processes include:

1、Comprehensive assessment of manufacturing partners’ engineering competencies prior to approval.

2、Mandatory alignment to DakingsRapid quality procedures, inspection guidelines, and documented control requirements.

3、Full and unambiguous communication of customer specifications to all certified partners.

4、Ongoing performance monitoring with data-driven feedback to support continuous supplier improvement.

5、Scheduled on-site verification of quality controls to ensure sustained compliance with DakingsRapid standards.

How does Dakingsrapid verify that parts meet the established specifications?

DakingsRapid uses four key methods to confirm that every part meets customer specifications:

1、Remote Inspection & Data Review

We evaluate part photographs and inspection measurement data directly from the manufacturing site.2、In-House QC Laboratory Testing

Partners may ship parts to our DakingsRapid quality lab for detailed verification, including dimensional checks, XRF material analysis, and cosmetic evaluation.3、On-Site Source Inspection

Our supplier quality engineers conduct in-person inspections at partner facilities to validate process controls and final part conformity.4、Independent Third-Party Testing

When needed, DakingsRapid works with accredited measurement providers to perform unbiased dimensional verification and non-destructive testing.

What actions does Dakingsrapid take if a manufacturing error occurs?

Dakingsrapid takes full responsibility for the quality of parts manufactured in our ecosystem. When a nonconformance is reported by Dakingsrapid Quality Control team, or by a Dakingsrapid customer, email alerts are sent to manufacturing partners in order to resolve the issue and also identify the root cause of the issue to inform the required improvement action reports.

When errors occur and the manufacturing partner submits root causes and improvement actions, we specifically look for the role the control plan plays in both the root cause of the issue and also in the solution to prevent this from recurring.

How does Dakingsrapid inspect parts for quality control?

All parts manufactured with dakingsrapid undergo inspections by our manufacturing partners, which are then verified by dakingsrapid either in-person or remotely. Our standard inspections verify critical dimensions using hand tools and cosmetic requirements and we can also perform advanced inspections using CMM or laser scanner technologies as well as first article inspections or other customer inspection plans such as PPAP upon request.

How will I be able to see the quality inspections performed on my parts?

After inspections are completed, all quality documentation is uploaded to the dakingsrapid platform for customers to easily access at any time through the “Orders” tab of their account. Customers can also view photos of their parts taken at inspection in real-time.